18 Years Factory Plastic Extruder/extruding Machine/press - Biaxially Oriented Die – Jwell Detail:

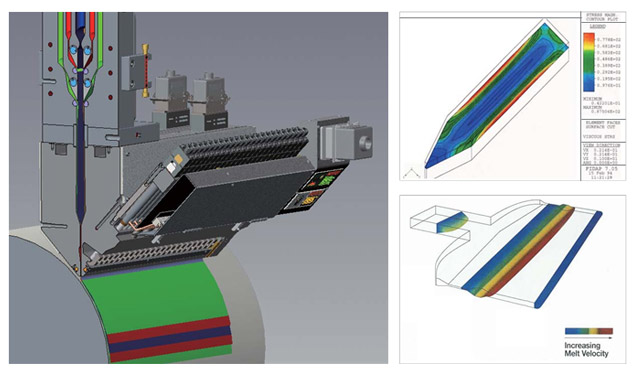

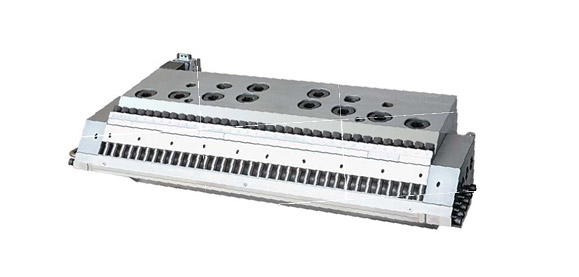

Biaxially Oriented Die

Product detail pictures:

Related Product Guide:

Global Twin-Screw Extruder market 2018 Provides an In-Depth Insight of Sales Analysis | Производственная Линия Ppr

Worldwide Medical Plastics Extrusion Market Study for 2018 to 2023 providing information on Key Players, Growth Drivers and Industry challenges | Extruded Plastic Tubing

We're going to commit ourselves to giving our esteemed buyers using the most enthusiastically considerate solutions for 18 Years Factory Plastic Extruder/extruding Machine/press - Biaxially Oriented Die – Jwell, The product will supply to all over the world, such as: Porto , Johor , Philippines , We would very much welcome an opportunity to do business with you and have pleasure in attaching further details of our products. Excellent quality, competitive prices,punctual delivery and dependable service can be guaranteed.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.

-

100% Original Zipper Profile Extruder - DYPS-X...

-

Cheapest Price Price Of Plastic Extrusion Machi...

-

Hot New Products Pe Pipe Extrusion Line - DYPS...

-

factory Outlets for Профильный Экструдер - JWZ...

-

professional factory for Polyethylene Hdpe Pipe...

-

2017 wholesale price Curtis Screw - PU/TPU rea...