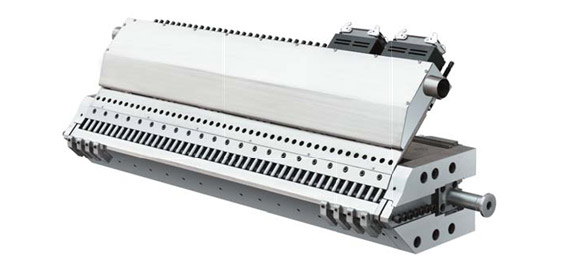

18 Years Factory Screw Mixer Design - Film Die Series – Jwell Detail:

Film Die Series

Product detail pictures:

Related Product Guide:

Plastics Machinery Shipments Recover in Third Quarter After Weaker Second Quarter : Plastics Technology | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

Extruders and Compounding Machines Market by top Key Vendors, Trends, Sales, Supply, Demand, Analysis and Forecasts to 2025 | Extruded Plastic Tubing

We usually continually offer you the most conscientious consumer services, along with the widest variety of designs and styles with finest materials. These initiatives include the availability of customized designs with speed and dispatch for 18 Years Factory Screw Mixer Design - Film Die Series – Jwell, The product will supply to all over the world, such as: Maldives , Myanmar , Algeria , We've a good reputation for stable quality solutions, well received by customers at home and abroad. Our company would be guided by the idea of "Standing in Domestic Markets, Walking into International Markets". We sincerely hope that we could do business with customers both at home and abroad. We expect sincere cooperation and common development!

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.

-

Cheap PriceList for Inside Clip-chain Extruder ...

-

High Quality Plastic Pellet Extruder - PVC Tra...

-

Reasonable price Extruder Manufacturer - WPC p...

-

Factory Price For Drink Straw Extruding Machine...

-

Cheap price Custom Pvc Plastic Profile Extrusio...

-

Excellent quality History Of Screws - PP Super...