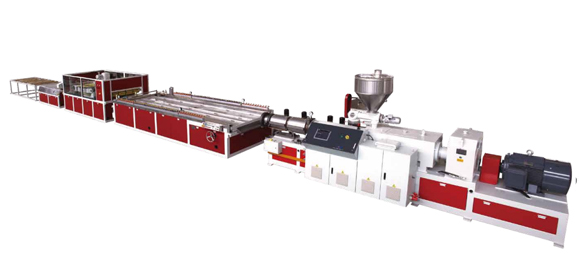

Bottom price Filament Extruding Machine - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell Detail:

XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology)

Product detail pictures:

Related Product Guide:

Spectrum Plastics Group Acquires Fermatex Vascular Technologies | Производственная Линия Ppr

45 победителей конкурса «Лидеры России» заняли высокие должности в администрации президента, федеральных и региональных ведомствах | Extruded Plastic Tubing

It truly is our responsibility to fulfill your requirements and successfully provide you. Your fulfillment is our best reward. We're seeking forward in your check out for joint development for Bottom price Filament Extruding Machine - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell, The product will supply to all over the world, such as: Bhutan , luzern , Ukraine , We also provide OEM service that caters to your specific needs and requirements. With a strong team of experienced engineers in hose design and development, we value every opportunity to provide best products for our customers.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.

-

China Manufacturer for Pvc Extruder Machine - ...

-

Manufactur standard Смеситель Для Маддока - YF...

-

Short Lead Time for Foam Moulding Machine - Fu...

-

Good Wholesale Vendors Pvc Coil Mat Making Mach...

-

Discountable price Pipe Extrusion Process - PV...

-

China Supplier Pc Hollow Section Sheet Extrusio...