Bottom price Filler Masterbatch Pelletizing Machine - Film Die Series – Jwell Detail:

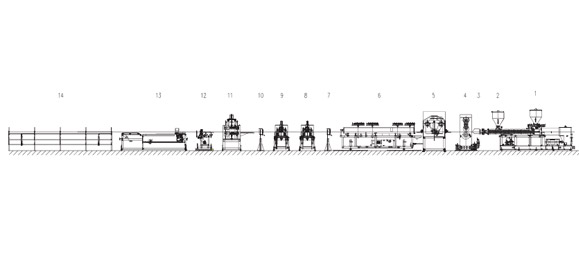

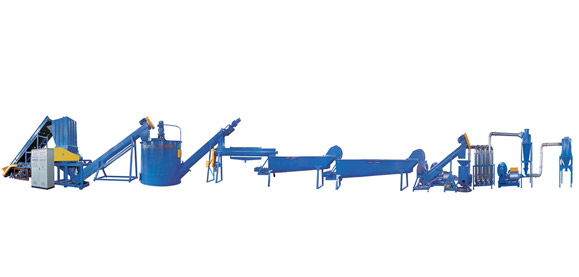

Film Die Series

Product detail pictures:

Related Product Guide:

Pharma 11 Twin-screw Extruder from Thermo Fisher Scientific : Get Quote, RFQ, Price or Buy | Wpc Extrusion Machine

Process Improvements Deliver Taste In Plant-Based Meat | Screw Extruder Machine

We have now a hugely efficient team to deal with inquiries from buyers. Our goal is "100% client gratification by our solution high-quality, rate & our team service" and take pleasure in a great popularity among clients. With several factories, we will provide a wide assortment of Bottom price Filler Masterbatch Pelletizing Machine - Film Die Series – Jwell, The product will supply to all over the world, such as: Latvia , venezuela , Ukraine , Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we will continue to develop, to provide the high-quality products and services, and promote lasting cooperation with our customers, common development and create a better future.

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.

-

Reasonable price for Twin Screw Extruder Cost -...

-

Low price for Машина Для Производства Пластиков...

-

Hot Selling for Plastic Corrugated Pipe Extrude...

-

Hot Selling for Cheap Plastic Extruder - DYQT ...

-

professional factory for Screw Special Design W...

-

Cheap price Yarn Making Machine - PC PMMA Opti...