Cheapest Factory Thermoplastic Extrusion - JWE Co-rotation Parallel Twin-screw Pelletizing Machine – Jwell Detail:

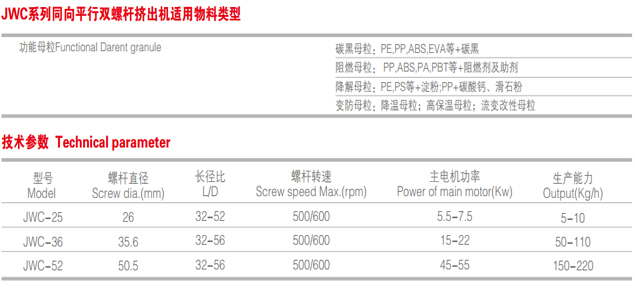

JWE Co-rotation Parallel Twin-screw Pelletizing Machine

Product detail pictures:

Related Product Guide:

Twin Screw Extruders Market 2023 by Opportunities, Restraints Product, Key Developments, Overview and Forecast | Производственная Линия Ppr

Worldwide Medical Plastics Extrusion Market Study for 2018 to 2023 providing information on Key Players, Growth Drivers and Industry challenges | Wpc Extrusion Machine

We also offer you product sourcing and flight consolidation expert services. We've our personal manufacturing unit and sourcing business. We can offer you virtually every variety of merchandise associated to our item range for Cheapest Factory Thermoplastic Extrusion - JWE Co-rotation Parallel Twin-screw Pelletizing Machine – Jwell, The product will supply to all over the world, such as: New York , Jordan , Guinea , We have now 48 provincial agencies in the country. We also have stable cooperation with several international trading companies. They place order with us and export solutions to other countries. We expect to cooperate with you to develop a larger market.

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,

-

Free sample for High Quality 38crmoala Bimetall...

-

China New Product Plastic Sheet Extrusion Machi...

-

Special Price for Screw For Extruder - JWP Ser...

-

Cheapest Price Pp Pe Screw And Barrel - UPVC P...

-

Lowest Price for Film Extrusion Machine Three S...

-

Personlized Products Plastic Extruder For Pp - ...