China Factory for Pvc Plastic Roofing Sheet Extruder - JWE Co-rotation Parallel Twin-screw Pelletizing Machine – Jwell Detail:

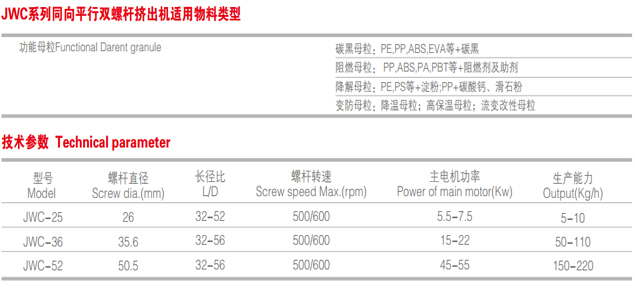

JWE Co-rotation Parallel Twin-screw Pelletizing Machine

Product detail pictures:

Related Product Guide:

IQMS Pinnacle 2018 | Screw Extruder Machine

Очерский машиностроительный завод активно модернизирует мощности по производству нефтепромыслового оборудования // В тренде // Новости | Extruded Plastic Tubing

We now have our individual sales group, layout team, technical team, QC crew and package group. Now we have strict high-quality control procedures for each procedure. Also, all of our workers are experienced in printing discipline for China Factory for Pvc Plastic Roofing Sheet Extruder - JWE Co-rotation Parallel Twin-screw Pelletizing Machine – Jwell, The product will supply to all over the world, such as: Kenya , Cancun , Panama , Being guided by customer demands, aiming at improving the efficiency and quality of customer service, we constantly improve goods and give more detailed services. We sincerely welcome friends to negotiate business and start cooperation with us. We hope to join hands with friends in different industries to create a brilliant future.

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,

-

Free sample for Одношнековый Экструдер Для Прод...

-

Big discounting Herbert Screw - XPE,IXPE Foami...

-

Online Exporter Spare Parts Of Extruder - WPC ...

-

Super Lowest Price Single Layer Sheet Extruder ...

-

New Arrival China Extruder Parallel Twin Screw ...

-

High reputation Головка - Hydraulic Screen Cha...