China OEM Machine Manufacturer -

JWE Co-rotation Parallel Twin-screw Pelletizing Machine – Jwell

Product Detail

Product Tags

Related Video

Feedback (2)

The shopper satisfaction is our primary focus on. We uphold a consistent level of professionalism, quality, credibility and repair for

Maddock Mixer

, Ldpe Extruder Machine

, Extrusion Molding Plastic

, We have now designed a reputable track record among many shoppers. Quality&customer initially are normally our constant pursuit. We spare no attempts to produce greater solutions. Stay up for long-term cooperation and mutual positive aspects!

China OEM Machine Manufacturer -

JWE Co-rotation Parallel Twin-screw Pelletizing Machine – Jwell Detail:

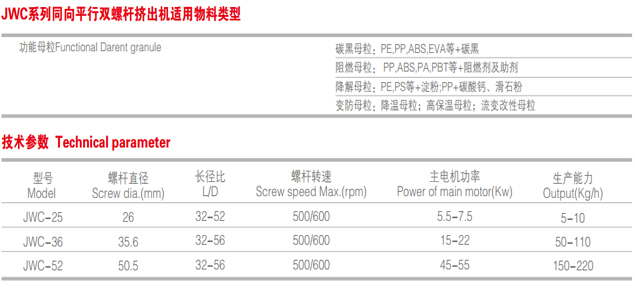

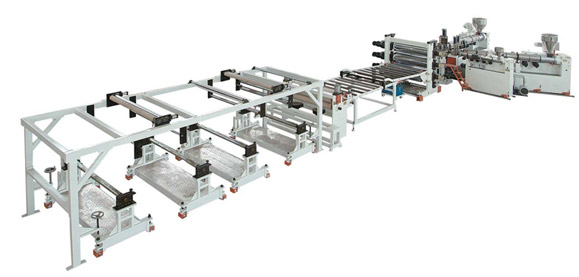

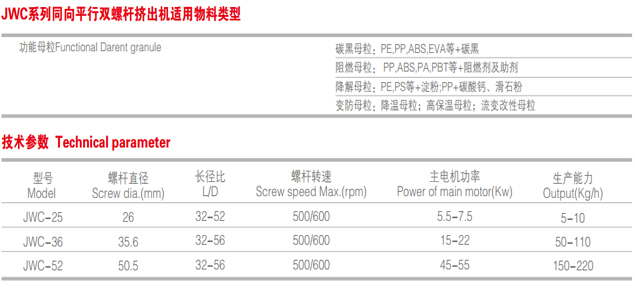

JWE Co-rotation Parallel Twin-screw Pelletizing Machine

- Building block type screw and barrel have the advantages of multi combination, wider applications. By changing the small quantity of barrel and screw elements, the screw and barrel can process different kinds of raw materials.

The barrels can be changed in accordance with the processing requirement

The building block type barrels enable more precise processing. The temperature of every barrel can be individually set. The surface of the barrel has been special treated for more wearable and anti-corrosive, so that the barrels can suitable for different raw materials.

High quality and stable gear distribution transmitting system .The system is designed with high torque, the gears are high precisely processed. With the reasonable oil immersion device and the force lubrication system and the chain protection device enable the extruder can be smoothly and stably running. From the very limited space, we designed a new style pivot with spline frame to ensure biggest bearing ability and realize high torque transmission Precise and convenient controlling system: Optional separate controlling unit, analogue panel display, PLC system, PEC system controlling.

Low vibration, low noise. The machine can be installed easily on the flat ground.

Product detail pictures:

Related Product Guide:

Publiscopie : La maîtrise totale des outillages pour l’extrusion thermoplastique | Screw Extruder Machine

Vacuum Packaging Machines Market Industry Outlook 2018 to 2025 | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

With a complete scientific quality management system, good quality and good faith, we win good reputation and occupied this field for

China OEM Machine Manufacturer -

JWE Co-rotation Parallel Twin-screw Pelletizing Machine – Jwell, The product will supply to all over the world, such as: Cannes

, panama

, South Africa

, Our company has a skillful sales team, strong economic foundation, great technical force, advanced equipment, complete testing means, and excellent after-sales services. Our products have beautiful appearance, fine workmanship and superior quality and win the unanimous approvals of the customers all over the world.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.

By Hedda

from USA

- 2015.09.21 11:44

By Hedda

from USA

- 2015.09.21 11:44

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.

By Frank

from Argentina

- 2015.06.19 10:42

By Frank

from Argentina

- 2015.06.19 10:42