Chinese Professional Линия Экструзии Листового Пресса - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell Detail:

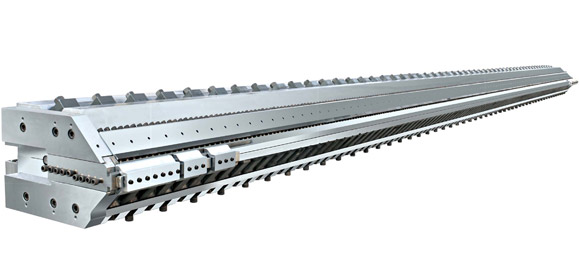

XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology)

Product detail pictures:

Related Product Guide:

EXTRUSION: Orientation: The Good and the Bad : Plastics Technology | Extruded Plastic Tubing

Транснефть | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

Our advantages are reduced prices,dynamic product sales workforce,specialized QC,solid factories,superior quality services for Chinese Professional Линия Экструзии Листового Пресса - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell, The product will supply to all over the world, such as: Victoria , Johannesburg , Cancun , Till now, the goods list has been updated regularly and attracted clients from around the globe. Detailed facts is often obtained in our web-site and you'll be served with premium quality consultant service by our after-sale group. They are going to help you get comprehensive acknowledge about our products and make a satisfied negotiation. Company go to to our factory in Brazil is also welcome at any time. Hope to obtain your inquiries for any pleased co-operation.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.

-

PriceList for Twin Plastic Extruder Screw And B...

-

One of Hottest for Plastic Extruding Machine - ...

-

2017 Latest Design Pvc Profiles For Wall And Ce...

-

Europe style for Plastic Extruder Machine Price...

-

OEM Factory for Screw And Barrel For 72 93 114 ...

-

New Fashion Design for Plastic Pipe Extrusion -...