Discountable price Wpc Profile Production Extrusion Line - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell Detail:

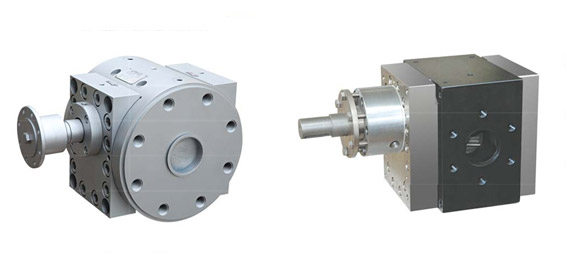

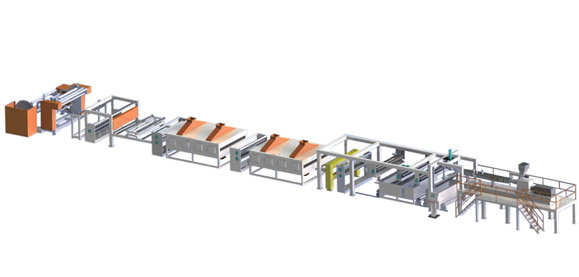

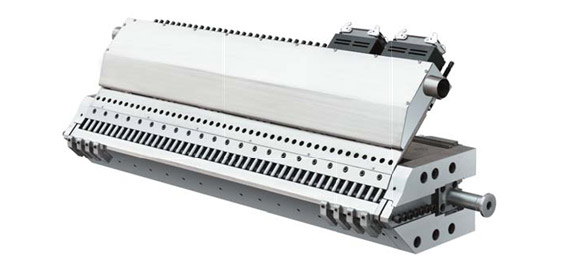

XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology)

Product detail pictures:

Related Product Guide:

Железнодорожники внедряют ремонт на закрытых перегонах | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

25 Years of Change: Industry veterans look back on the past quarter century | Extruded Plastic Tubing

We support our purchasers with ideal high-quality merchandise and significant level company. Becoming the specialist manufacturer in this sector, we now have received loaded practical encounter in producing and managing for Discountable price Wpc Profile Production Extrusion Line - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell, The product will supply to all over the world, such as: Turkmenistan , Surabaya , Durban , We guarantee that our company will try our best to reduce customer purchase cost , shorten the period of purchase , stable products quality , increase customers' satisfaction and achieve win-win situation .

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.

-

Trending Products Soft Pvc Extrusion Profile - ...

-

Well-designed Wpc Floor Extruder - Plastic Mel...

-

High Performance Extruder Machine Ptfe - DYPS ...

-

Super Purchasing for Экструзионная Линия Для Тр...

-

Online Exporter Second Hand Insulation Extruder...

-

Hot Selling for Epe Sheet Single Screw Extruder...