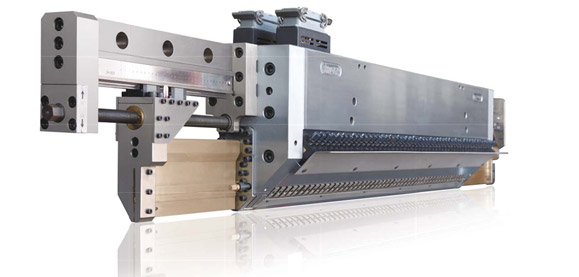

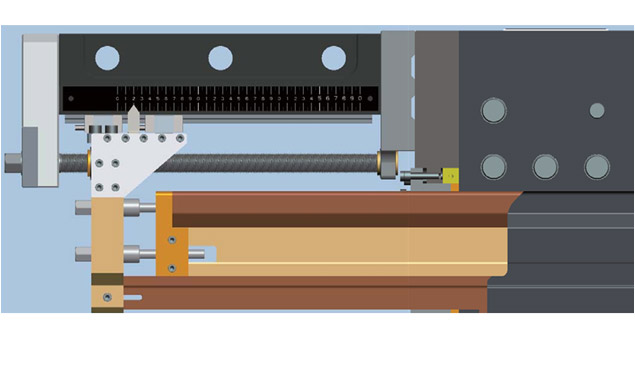

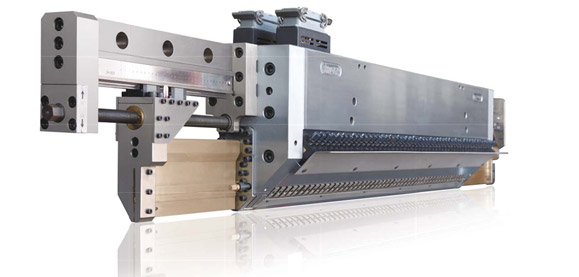

Factory Cheap Plastic Extrusion Design Guide - High-speed Film Coating Die Series – Jwell Detail:

High-speed Film Coating Die Series

Product detail pictures:

Related Product Guide:

Global Medical Tubing Market Report 2018-2022 – Analysis by Material, Application, and Structure | Wpc Extrusion Machine

NewAge(R) Industries Donates More Laptop Computers to a Rural Cambodian School; Further Increases Students Access to Education | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

During the past few years, our business absorbed and digested state-of-the-art technologies the two at home and abroad. Meanwhile, our firm staffs a group of experts devoted to your development of Factory Cheap Plastic Extrusion Design Guide - High-speed Film Coating Die Series – Jwell, The product will supply to all over the world, such as: Jordan , Hamburg , Barbados , Profession, Devoting are always fundamental to our mission. We've got always been in line with serving customers, creating value management objectives and adhering to the sincerity, dedication, persistent management idea.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!

-

Good Quality Drip Irrigation Pipe Making Machin...

-

Big Discount Plastic Production Line - JWE Co-...

-

Hot sale Pvc Pipe Twin Screw Extruder - PVC、P...

-

China Cheap price Plastic Cup Sheet Extrusion M...

-

Competitive Price for Foam Plate Making Machine...

-

Chinese wholesale Psp Foam Sheet Extruder - Sh...