factory customized Roto Moulding For Plastic Extruder Machine Manufacturer - High-speed Film Coating Die Series – Jwell Detail:

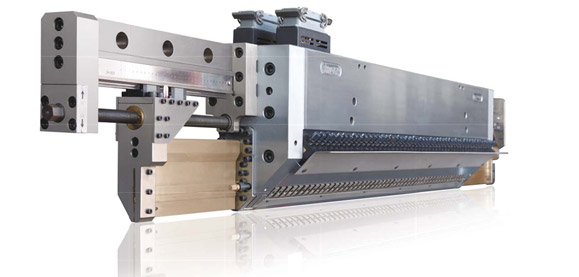

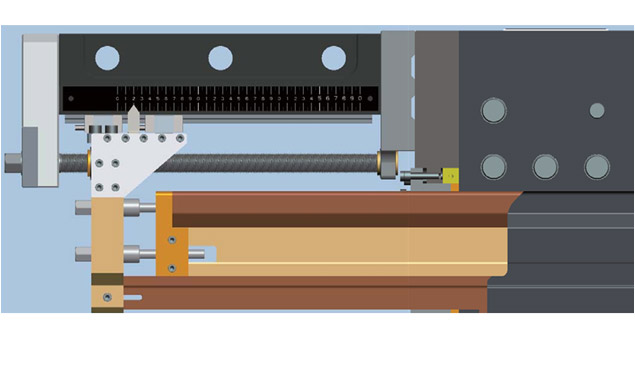

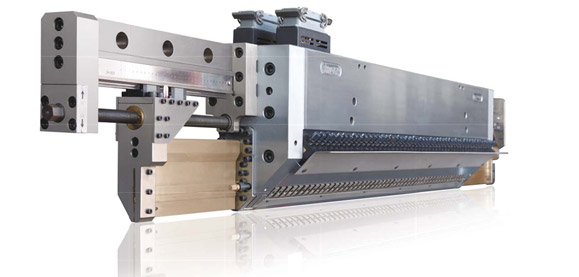

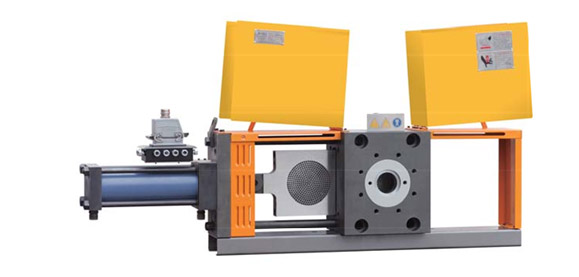

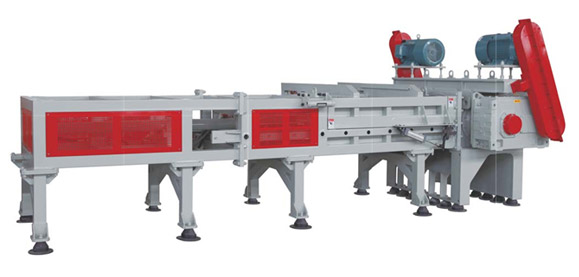

High-speed Film Coating Die Series

Product detail pictures:

Related Product Guide:

Extrusion Cooling: It’s All About Turbulence : Plastics Technology | Extruded Plastic Tubing

Booms and Busts in Twin-screw Extruders Market | Data Includes Research News | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

Sticking for the basic principle of "Super Top quality, Satisfactory service" ,We've been striving to be an excellent business enterprise partner of you for factory customized Roto Moulding For Plastic Extruder Machine Manufacturer - High-speed Film Coating Die Series – Jwell, The product will supply to all over the world, such as: Honduras , Leicester , Ukraine , So that you can utilize the resource from the expanding info in international trade, we welcome shoppers from everywhere on-line and offline. In spite of the good quality solutions we provide, effective and satisfying consultation service is supplied by our professional after-sale service team. Product lists and detailed parameters and any other info weil be sent to you timely for your inquiries. So you should make contact with us by sending us emails or call us if you have any questions about our corporation. ou may also get our address info from our web page and come to our company to get a field survey of our merchandise. We've been confident that we have been going to share mutual achievement and create strong co-operation relations with our companions in this marketplace. We're searching forward for your inquiries.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!

-

Special Price for Extruder Screw Design Of Batt...

-

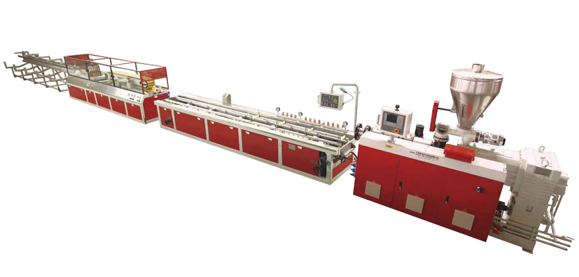

Discount wholesale Wpc Production Line - Sheet...

-

One of Hottest for Pvc Screw Extruding Equipmen...

-

Factory making Twin Screw Extruder Gearbox Desi...

-

Factory made hot-sale Wiper Blade Rubber Extrus...

-

Free sample for High Quality 38crmoala Bimetall...