Factory directly Шнек Для Экструдера - DYQX Series Lumpish Plastic, Film Crushing, Washing And Recycling Line – Jwell Detail:

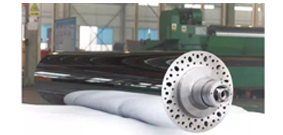

DYQX Series Lumpish Plastic, Film Crushing, Washing And Recycling Line

Product detail pictures:

Related Product Guide:

Роснефть в сентябре 2018 г остановит АНХК на ремонт // Нефтехимия // Новости | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

Forest Twin Screw Extruders Market Evolving Industry Trends and Key Insights by 2024 | Wpc Extrusion Machine

Our enterprise since its inception, often regards solution excellent as enterprise life, continually strengthen output technology, enhance product high quality and continually strengthen organization total high-quality administration, in strict accordance using the national standard ISO 9001:2000 for Factory directly Шнек Для Экструдера - DYQX Series Lumpish Plastic, Film Crushing, Washing And Recycling Line – Jwell, The product will supply to all over the world, such as: Romania , Detroit , Hyderabad , Each customer's satisfactory is our goal. We are looking for long-term cooperation with each customer. To meet this, we keep up our quality and provide extraordinary customer service. Welcome to our company, we are expecting to cooperate with you.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!

-

Excellent quality Pvc Pipe Making Machine - EV...

-

Wholesale Rubber Outsole Extruder Machine - Su...

-

Cheap price rotating Twin Screw Extruder Price ...

-

Best Price for Pvc Pellet Machine - PP Non-wov...

-

Quality Inspection for Plastic Wire Drawing Mak...

-

Hot sale Экструзия/Поточная Линия Потолочной Па...