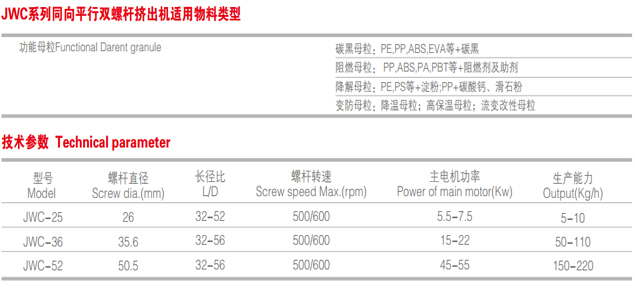

Factory directly Sheet Extruder Line - JWE Co-rotation Parallel Twin-screw Pelletizing Machine – Jwell Detail:

JWE Co-rotation Parallel Twin-screw Pelletizing Machine

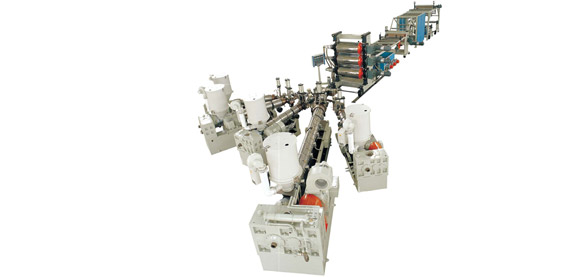

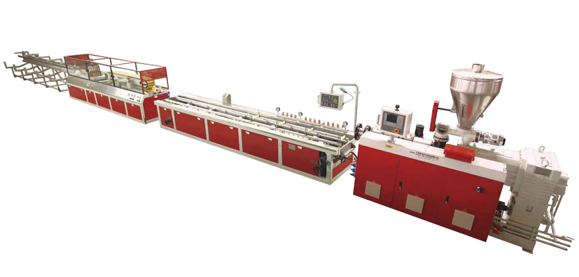

Product detail pictures:

Related Product Guide:

«У нас уже только ноздри торчат из этого мусора. Еще чуть-чуть | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

New Surfing Fin Made With Recycled WPC : Plastics Technology | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

We can constantly satisfy our respected customers with our good high quality, good price tag and good support due to we have been additional specialist and extra hard-working and do it in cost-effective way for Factory directly Sheet Extruder Line - JWE Co-rotation Parallel Twin-screw Pelletizing Machine – Jwell, The product will supply to all over the world, such as: Panama , Hongkong , Azerbaijan , Today, We are with great passion and sincerity to further fulfill our global customers' needs with good quality and design innovation. We fully welcome customers from all over the world to establish stable and mutually beneficial business relationships, to have a bright future together.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.

-

Renewable Design for Extrusion Upvc Molding Pro...

-

OEM Customized 45 Single Screw Extruder - Acce...

-

Factory Promotional Fuel Less Power Plastic Ext...

-

Big discounting Auto Screen Changer For Pp Extr...

-

factory low price Epe Single Screw Plastic Extr...

-

100% Original Plastic Film Making Machine Price...