Factory For Дизайн Шнека - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell Detail:

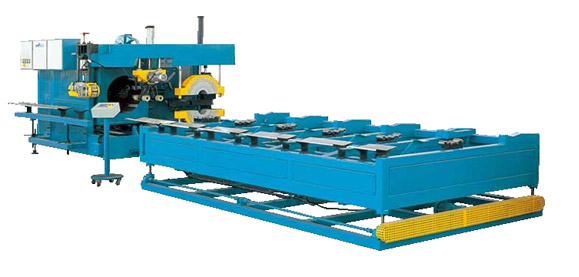

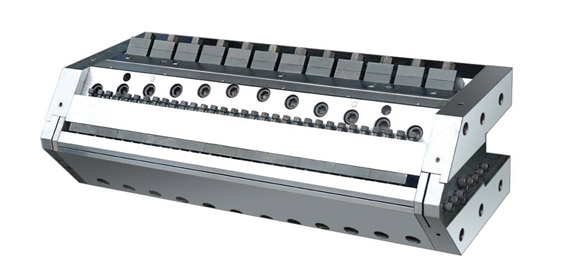

XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology)

Product detail pictures:

Related Product Guide:

Когда у Белорусских цементных заводов откроется второе дыхание | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

EXTRUSION: Orientation: The Good and the Bad : Plastics Technology | Screw Extruder Machine

"Sincerity, Innovation, Rigorousness, and Efficiency" would be the persistent conception of our corporation to the long-term to establish collectively with customers for mutual reciprocity and mutual benefit for Factory For Дизайн Шнека - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell, The product will supply to all over the world, such as: Rwanda , Angola , South Korea , "Good quality, Good service " is always our tenet and credo. We take every effort to control the quality, package, labels etc and our QC will check every detail during producing and before shipment. We have been willing to establish long business relationship with all those who seek the high quality products and good service. We've got set up a wide sales network across European countries, North of America, South of America, Middle East, Africa, East Asia countries.Please contact us now, you will find our expert experience and high quality grades will contribute to your business.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.

-

Big Discount Pe Foam Pipe Plastic Machine - JW...

-

Professional Design Single Screw Vs Twin Screw ...

-

China Manufacturer for Plastic Bag Making Machi...

-

Lowest Price for Dwc Pipe Machine - Hot Mill R...

-

Hot Selling for Screw Design For Pvc - Sheet D...

-

Discount wholesale Plastic Material Kneader Ext...