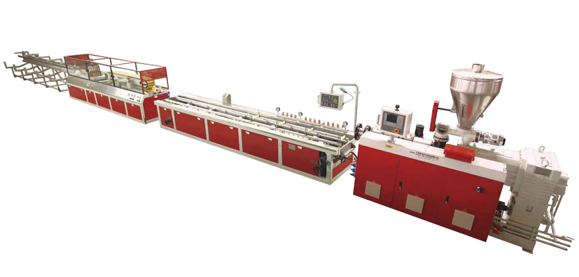

Factory For Twin Screw Extruder Elements - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell Detail:

XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology)

Product detail pictures:

Related Product Guide:

Twin-Screw Extruder Market In Depth 2018 -2025 Size, Growth And Swot Analysis By Key Players: Matila, Toshiba Machine, Flytech, Xtrutech, Coperion | Extruded Plastic Tubing

JELU: Bioplastic for Furniture Making | Производственная Линия Ppr

Now we have highly developed devices. Our items are exported towards the USA, the UK and so on, enjoying a great popularity among the customers for Factory For Twin Screw Extruder Elements - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell, The product will supply to all over the world, such as: France , Holland , kazakhstan , With the goal of "zero defect". To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

We have worked with many companies, but this time is the best,detailed explanation, timely delivery and quality qualified, nice!

-

Massive Selection for Pvc Window Sill Panel Pro...

-

Popular Design for Pe Pvc Pipe Extruding Machin...

-

PriceList for Vertica Cable Duct - JWZ-BM3D-10...

-

Newly Arrival U-pvc Profiles Production Line - ...

-

Massive Selection for Single Screw Barrel For F...

-

Short Lead Time for Винт Смешивания Maddock - ...