Factory Free sample Rigid Plastic Profiles - JWE Co-rotation Parallel Twin-screw Pelletizing Machine – Jwell Detail:

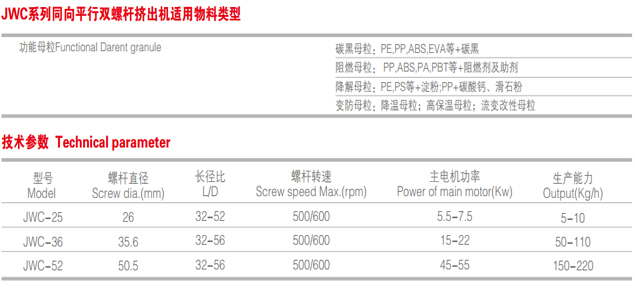

JWE Co-rotation Parallel Twin-screw Pelletizing Machine

Product detail pictures:

Related Product Guide:

Когда у Белорусских цементных заводов откроется второе дыхание | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

Global Conical Twin Screw Extruder Market 2018 – Zhangjiagang Xinweier, Esde, Battenfeld-Cincinnati, Toshiba Machine | Extruded Plastic Tubing

Our group through specialist training. Skilled expert knowledge, sturdy sense of assistance, to fulfill the provider needs of shoppers for Factory Free sample Rigid Plastic Profiles - JWE Co-rotation Parallel Twin-screw Pelletizing Machine – Jwell, The product will supply to all over the world, such as: Frankfurt , Ukraine , Belgium , We have exported our products all over the world, especially the USA and European countries. Furthermore, all of our products are manufactured with advanced equipment and strict QC procedures to ensure high quality.If you are interested in any of our products, please don't hesitate to contact us. We will try our best to meet your needs.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!

-

Quality Inspection for Designer Unique Waste Pv...

-

Special Design for Extrusion Screw And Barrel -...

-

Lowest Price for Film Extrusion Machine Three S...

-

Competitive Price for Foam Board Production Lin...

-

18 Years Factory Screw Barrel For Pvc - ABS、H...

-

Best Price on Pipe Machine Manufacturer - Stee...