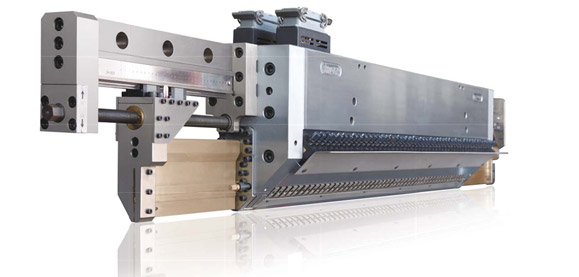

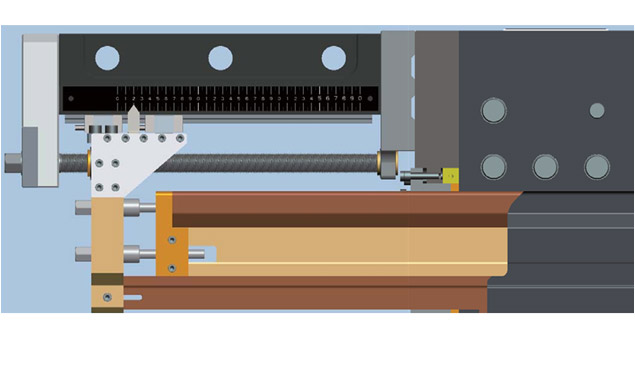

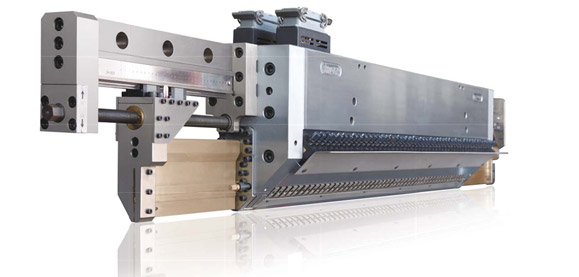

Factory Price Lab Twin Screw Extruder - High-speed Film Coating Die Series – Jwell Detail:

High-speed Film Coating Die Series

Product detail pictures:

Related Product Guide:

A new insight into high-strength Ti62Nb12.2Fe13.6Co6.4Al5.8 alloys with bimodal microstructure fabricated by semi-solid sintering | Wpc Extrusion Machine

Process Improvements Deliver Taste In Plant-Based Meat | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

Bear "Customer initially, High quality first" in mind, we do the job closely with our customers and supply them with efficient and skilled providers for Factory Price Lab Twin Screw Extruder - High-speed Film Coating Die Series – Jwell, The product will supply to all over the world, such as: Ukraine , Morocco , Frankfurt , Our products are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is "to continue to earn your loyalty by dedicating our efforts to the constant improvement of our products and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate".

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.

-

Reliable Supplier Construction Upvc Profiles - ...

-

2017 Good Quality Lab Single Screw Extruding Eq...

-

factory low price Extruder Parts - Plastic And...

-

Lowest Price for Dwc Pipe Machine - Hot Mill R...

-

Reliable Supplier High Speed Plastic Pipe Singl...

-

Factory directly Wenger Extruder - Single Scre...