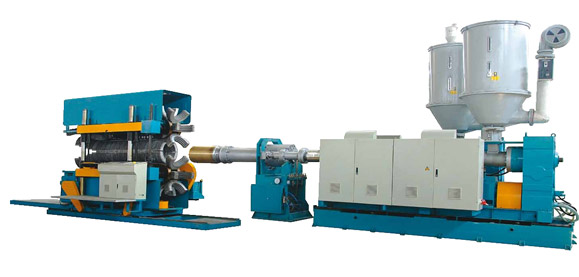

Factory selling Extrusion Moulding Machine - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell Detail:

XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology)

Product detail pictures:

Related Product Guide:

MedAccred adds plastic extrusion to audit criteria | Wpc Extrusion Machine

Registration Opens for Extrusion 2018 Conference : Plastics Technology | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

We pursue the administration tenet of "Quality is exceptional, Assistance is supreme, Reputation is first", and will sincerely create and share success with all clients for Factory selling Extrusion Moulding Machine - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell, The product will supply to all over the world, such as: Qatar , Egypt , Argentina , Our technical expertise, customer-friendly service, and specialized products make us/company name the first choice of customers and vendors. We are looking for your inquiry. Let's set up the cooperation right now!

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.

-

PriceList for Plastic Profile Extrusion Machine...

-

100% Original Polystyrene Frame Moulding - Sma...

-

Hot sale Factory Extruder Machine Manufacturer ...

-

Cheap PriceList for Hdpe Pipe Extrusion Machine...

-

Discount Price Pvc Plastic Profile Extrusion - ...

-

China OEM Pvc Foam Board Extrusion Machine - S...