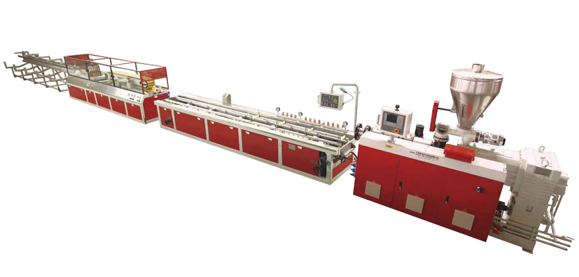

Factory selling Plastic Screw Extruder - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell Detail:

XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology)

Product detail pictures:

Related Product Guide:

New Surfing Fin Made With Recycled WPC : Plastics Technology | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

Food Extruders Market Report Product Category, Market Scope, Key Players, Retail Prices and Market Prospects 2018-2025 | Extruded Plastic Tubing

We're going to dedicate ourselves to offering our esteemed shoppers with the most enthusiastically considerate solutions for Factory selling Plastic Screw Extruder - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell, The product will supply to all over the world, such as: Argentina , Latvia , Germany , All the imported machines effectively control and guarantee the machining precision for the products. Besides, we have a group of high-quality management personnels and professionals, who make the high-quality products and have the ability to develop new products to expand our market home and abroad. We sincerely expect customers come for a blooming business for both of us.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.

-

Good Wholesale Vendors Пенообразователь - PVC ...

-

China Cheap price Hot Sell Pp Plastic Granules ...

-

Factory Price Двухшнековый Экструдер Buhler - ...

-

Factory Cheap Hot Extruding Plastic Garbage Bag...

-

Leading Manufacturer for Разница Между Одношнек...

-

China wholesale Extrusion Profile Pvc - Plasti...