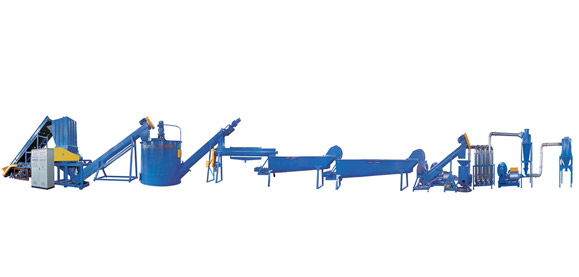

Factory supplied Plastic Channel Extrusion - Film Die Series – Jwell Detail:

Film Die Series

Product detail pictures:

Related Product Guide:

Когда у Белорусских цементных заводов откроется второе дыхание | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

Приказ Минтруда об утверждении Правил по охране труда при работе на высоте — Российская газета | Производственная Линия Ppr

To be the stage of realizing dreams of our employees! To build a happier, far more united and far more specialist team! To reach a mutual profit of our customers, suppliers, the society and ourselves for Factory supplied Plastic Channel Extrusion - Film Die Series – Jwell, The product will supply to all over the world, such as: Kyrgyzstan , Danish , Morocco , The credibility is the priority, and the service is the vitality. We promise we have the ability to provide excellent quality and reasonable price products for customers. With us, your safety is guaranteed.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.

-

professional factory for Drip Irrigation Pipe E...

-

Cheapest Factory Пластиковая Экструзионная Маши...

-

OEM Supply Линия Экструзии Труб Hdpe - Subsequ...

-

Professional China Части Экструдера - HDPE Wat...

-

Manufactur standard Смеситель Для Маддока - DY...

-

High Quality for Double Wall Corrugated Pipe Fo...