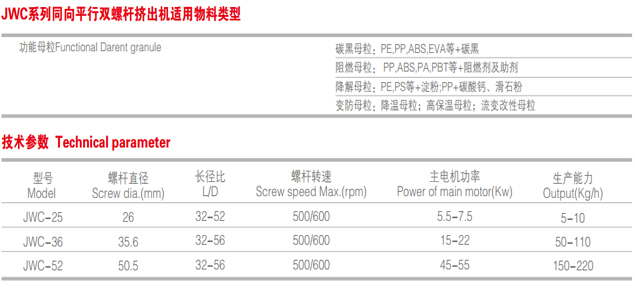

Factory supplied Twin Screw Extruder Working Principle - JWE Co-rotation Parallel Twin-screw Pelletizing Machine – Jwell Detail:

JWE Co-rotation Parallel Twin-screw Pelletizing Machine

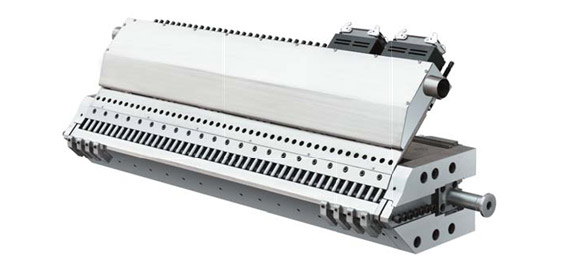

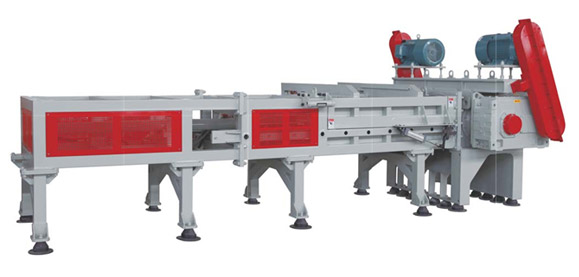

Product detail pictures:

Related Product Guide:

«Вы уже наметили, кто сядет в тюрьму, когда рухнут подъезды наших домов?!» | Extruded Plastic Tubing

Process Improvements Deliver Taste In Plant-Based Meat | Производственная Линия Ppr

The key to our success is "Good Product Quality, Reasonable Price and Efficient Service" for Factory supplied Twin Screw Extruder Working Principle - JWE Co-rotation Parallel Twin-screw Pelletizing Machine – Jwell, The product will supply to all over the world, such as: Ethiopia , Pakistan , Haiti , The company has perfect management system and after-sales service system. We devote ourselves to building a pioneer in the filter industry. Our factory is willing to cooperate with different customers domestic and overseas to gain better and better future.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.

-

8 Year Exporter Gum Extruder Machine - Large D...

-

High reputation Twin Screw Extruders A Basic Un...

-

Big discounting Upvc Frame Window Profile - Sh...

-

Well-designed Pet Strap Band Extrusion Machine ...

-

New Arrival China Screw And Barrel Plastic Extr...

-

Cheapest Price Ppr Water Pipe Extruder Machine ...