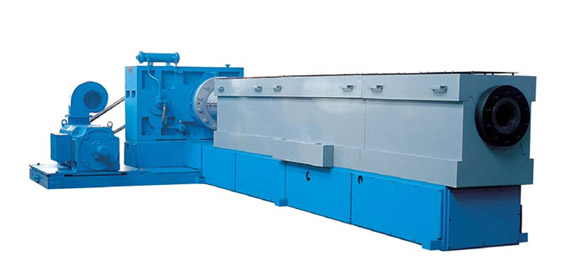

Factory wholesale Plastic Zip Lock Extruding Machine - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell Detail:

XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology)

Product detail pictures:

Related Product Guide:

3devo Introduces Two New Series of Filament Extruders | 3DPrint.com | Extruded Plastic Tubing

Extruding Machines Market Forecast – Industry Value, Market Size, Top Companies and General Trends for 2018-2025 | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

Our solutions are widely regarded and trustworthy by consumers and may meet continually modifying financial and social requirements for Factory wholesale Plastic Zip Lock Extruding Machine - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell, The product will supply to all over the world, such as: Jersey , Turin , Hamburg , There are advanced producing & processing equipment and skilled workers to ensure the merchandise with high quality. We've got found an excellent before-sale, sale, after-sale service to ensure the customers that could rest assured to make orders. Until now our merchandise are now moving on fast and very popular in South America, East Asia, the Middle east, Africa, etc.

This supplier offers high quality but low price products, it is really a nice manufacturer and business partner.

-

2017 wholesale price Ldpe Zipper Machinery - F...

-

2017 Good Quality Cpvc Pipe And Fittings Machin...

-

Big discounting Pe Pipe Making Machine - Hot M...

-

Well-designed High Quality Pvc Pipe Machine/twi...

-

OEM China 3 Layer Aba Pe Film Extruder Machine ...

-

Good quality Single Screw Extruder Price - Spi...