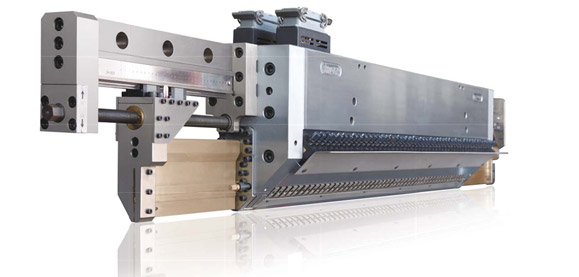

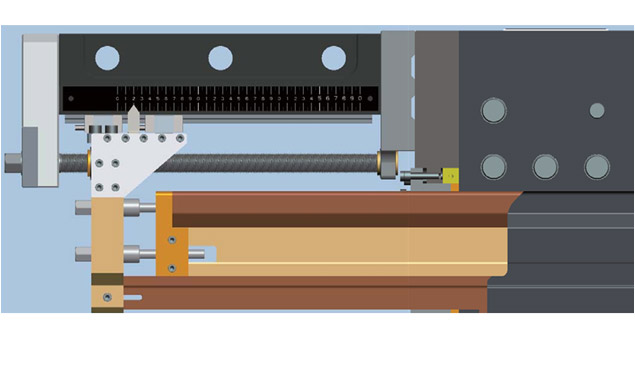

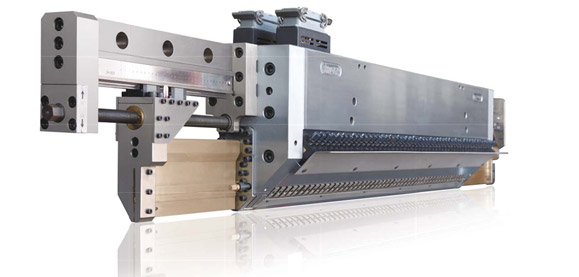

Hot sale Factory Custom Plastic Hollow Extrusions - High-speed Film Coating Die Series – Jwell Detail:

High-speed Film Coating Die Series

Product detail pictures:

Related Product Guide:

Can an audiophile find joy in an under $100 amplifier? | Screw Extruder Machine

Latest mechanical, hydraulic and screw extrusion presses for briquetting applications available from Briquetting Systems | Производственная Линия Ppr

Our business promises all users of the first-class items and the most satisfying post-sale company. We warmly welcome our regular and new prospects to join us for Hot sale Factory Custom Plastic Hollow Extrusions - High-speed Film Coating Die Series – Jwell, The product will supply to all over the world, such as: Brunei , India , Serbia , As the world economic integration bringing challenges and opportunities to the xxx industry, our company , by carrying on our teamwork, quality first, innovation and mutual benefit, are confident enough to supply our clients sincerely with qualified merchandise, competitive price and great service, and to build a brighter future under the spirit of higher, faster, stronger with our friends together by carrying on our discipline.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!

-

Factory Promotional Пластиковые Экструдеры - P...

-

Wholesale Brabender Twin Screw Extruder - PVC ...

-

Reliable Supplier China Reinforced Ppr Pipe Ext...

-

PriceList for Hard Plastic Profile - WPC pelle...

-

Discountable price Что Такое Двухшнековый Экстр...

-

Free sample for Drip Irrigation Pipe Production...