Hot Sale for Extruding Granulator - Hollow Cross Section Plate Die Series – Jwell Detail:

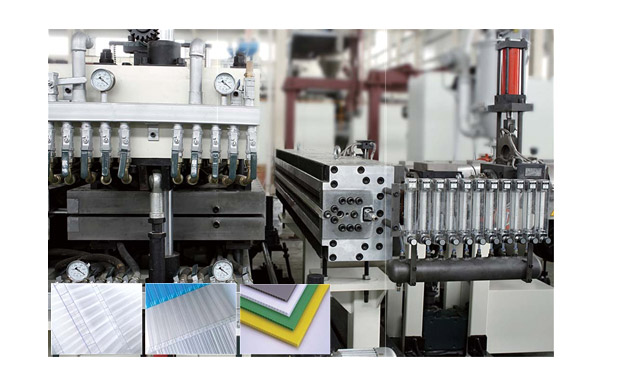

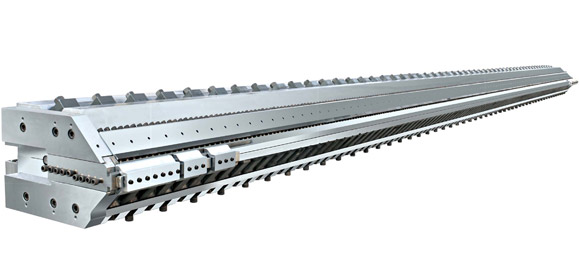

Hollow Cross Section Plate Die Series

Product detail pictures:

Related Product Guide:

Global Twin-Screw Extruder market 2018 Provides an In-Depth Insight of Sales Analysis | Wpc Extrusion Machine

Latest mechanical, hydraulic and screw extrusion presses for briquetting applications available from Briquetting Systems | Производственная Линия Ppr

Our advancement depends over the highly developed devices, excellent talents and continually strengthened technology forces for Hot Sale for Extruding Granulator - Hollow Cross Section Plate Die Series – Jwell, The product will supply to all over the world, such as: Cancun , Guyana , Liverpool , We have now a good reputation for stable quality goods, well received by customers at home and abroad. Our company would be guided by the idea of "Standing in Domestic Markets, Walking into International Markets". We sincerely hope that we could do business with car manufacturers, auto part buyers and the majority of colleagues both at home and abroad. We expect sincere cooperation and common development!

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.

-

Trending Products Soft Pvc Extrusion Profile - ...

-

Reasonable price for Recycling Extruder Machine...

-

Factory Cheap Hot Pvc Frame Extrusion - PE160 ...

-

High Performance Plastic Pipe Extrusion Machine...

-

Wholesale Price China Pvc Extrusion Chamfer - ...

-

Hot Selling for Screw Design For Pvc - Functio...