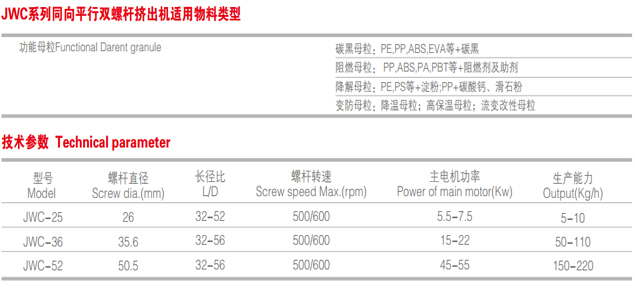

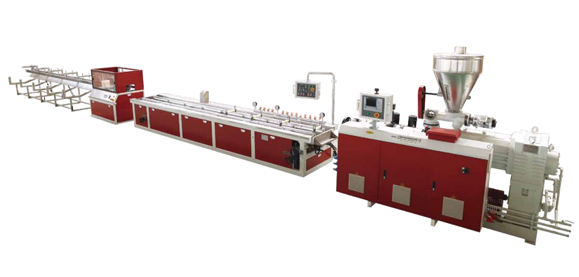

Hot Sale for High Performance Screw And Barrel For Plastic Extruder Machine - JWE Co-rotation Parallel Twin-screw Pelletizing Machine – Jwell Detail:

JWE Co-rotation Parallel Twin-screw Pelletizing Machine

Product detail pictures:

Related Product Guide:

Судостроительная отрасль Крыма | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

Process Improvements Deliver Taste In Plant-Based Meat | Wpc Extrusion Machine

Our target is always to satisfy our customers by offering golden support, superior value and high quality for Hot Sale for High Performance Screw And Barrel For Plastic Extruder Machine - JWE Co-rotation Parallel Twin-screw Pelletizing Machine – Jwell, The product will supply to all over the world, such as: Zambia , Guatemala , Mexico , Our company follows laws and international practice. We promise to be responsible for friends, customers and all partners. We would like to establish a long-term relationship and friendship with every customer from all over the world on the basis of mutual benefits. We warmly welcome all old and new customers to visit our company to negotiate business.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.

-

Original Factory Black U Channel Plastic Extrus...

-

2017 New Style Hopper Plastic Screw Feeder - P...

-

Cheap price Pp Extruder Machine - RTP Composit...

-

Wholesale Dealers of Pvc Single Wall Corrugated...

-

Best Price for Plastic Pipe Machine - High Cap...

-

OEM Manufacturer Plastic Twin Screw Extruder Fo...