Leading Manufacturer for Bubble Wrap Machine -

Hollow Cross Section Plate Die Series – Jwell

Product Detail

Product Tags

Related Video

Feedback (2)

Reliable quality and good credit standing are our principles, which will help us at a top-ranking position. Adhering to the tenet of "quality first, customer supreme" for

Co Rotating Twin Screw Extruder

, Plastic Extrusion Machine Manufacturers

, Double Screw Extruder Machine

, Welcome to visit our company and factory. Please feel free to get in touch with us if you need any further assistance.

Leading Manufacturer for Bubble Wrap Machine -

Hollow Cross Section Plate Die Series – Jwell Detail:

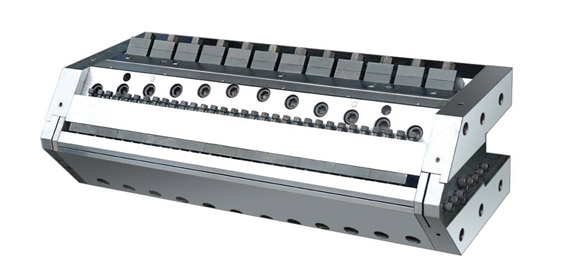

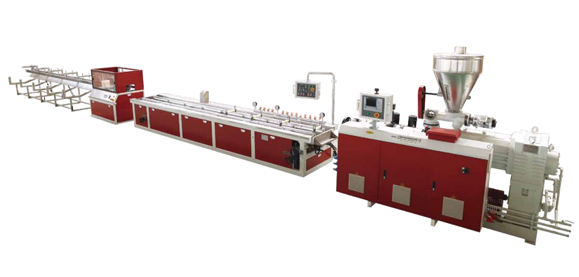

Hollow Cross Section Plate Die Series

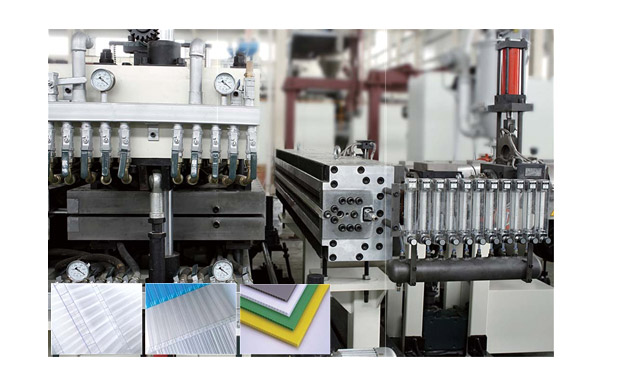

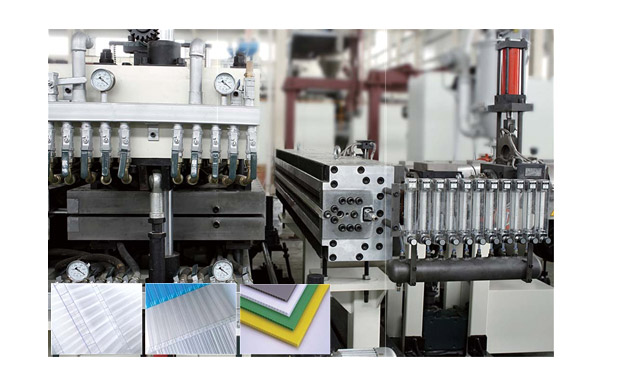

PC hollow plate used widely in constructions and decorations.The hollow grid plate die and feedblock can make UV protection on both sides.The final production with a max width of 2100mm and have a high impact strengh, good weather resistance and UV protection.With adjustable upper and lower

mold lips, production thickness relative errors can be controlled within 3%; built-in heater features provides fast heating and superior temperature retainment.The individual air regulator can make the air volume of each section even easy to control to increase the product quality.The smoothness

of the channel reaches 0.015- 0.03um,which ensures the stagnation-proof.

Different design can meet the different requirements of products, general polycarbonate hollow plate whose thickness is between 4 to 25mm, multi-layers plate such as H-cross section, X-cross section etc, the thickness of some can reach 36mm, and the UV layer can be coated. The PP, PE hollow grid plate produced by special dies are light weighted, dampproof and have a high impact strength, which is widely used as

advertising light panel, exhibition upholster, carry box etc.The thickness-range is 2-12mm and the width is 1200-2200mm.

The cooling vacuume calibrator is manufactured from specially treated material assuring maximum wear resistance and deformation-free. Special temperature controlled water way and vaccum calibration design allows temperature adjustment to meet various physical property requirements for different materials.

Product detail pictures:

Related Product Guide:

45 победителей конкурса «Лидеры России» заняли высокие должности в администрации президента, федеральных и региональных ведомствах | Screw Extruder Machine

How Aluminium Extrusions Are Constructed

We have been ready to share our knowledge of internet marketing worldwide and recommend you suitable merchandise at most aggressive rates. So Profi Tools present you very best price of money and we are ready to develop alongside one another with

Leading Manufacturer for Bubble Wrap Machine -

Hollow Cross Section Plate Die Series – Jwell, The product will supply to all over the world, such as: Zurich

, Azerbaijan

, Southampton

, Our company upholds the spirit of "innovation, harmony, team work and sharing, trails, pragmatic progress". Give us a chance and we will prove our capability. With your kind help, we believe that we can create a bright future with you together.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.

By Freda

from Zurich

- 2016.07.28 15:46

By Freda

from Zurich

- 2016.07.28 15:46

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.

By Alexandra

from Peru

- 2015.10.01 14:14

By Alexandra

from Peru

- 2015.10.01 14:14