Massive Selection for Twin Screws Barrel Extruder Screw Design - Subsequent Equipment – Jwell Detail:

Subsequent Equipment

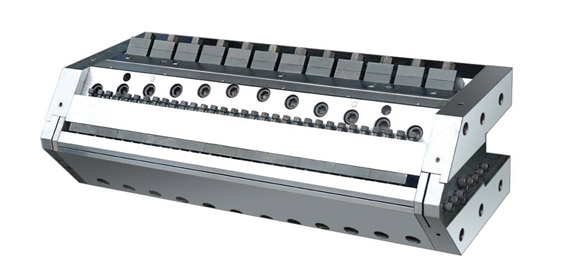

Product detail pictures:

Related Product Guide:

Нововоронежская АЭС: на энергоблоке №4 впервые установят новейшую систему аварийного охлаждения зоны реактора | Wpc Extrusion Machine

Forest Twin Screw Extruders Market Evolving Industry Trends and Key Insights by 2024 | Wpc Extrusion Machine

With a positive and progressive attitude to customer's interest, our company continuously improves our product quality to meet the needs of customers and further focuses on safety, reliability, environmental requirements, and innovation of Massive Selection for Twin Screws Barrel Extruder Screw Design - Subsequent Equipment – Jwell, The product will supply to all over the world, such as: Thailand , Cannes , Mombasa , Our Company policy is "quality first, to be better and stronger, sustainable development" . Our pursuit goals is "for society, customers, employees, partners and enterprises to seek reasonable benefit". We aspirate to do cooperate with all different the auto parts manufacturers, repair shop, auto peer , then create a beautiful future! Thank you for taking time to browse our website and we would welcome any suggestions you may have that can help us to improve our site.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!

-

Factory Price For Monofilament Extrusion Danlin...

-

Big Discount Polyethylene Extruder Machine - D...

-

China Gold Supplier for Mixing Extruder - Shee...

-

Wholesale Price China Extrusion Profile Strip -...

-

OEM manufacturer Filtrability Test Lab Single S...

-

Popular Design for Одношнековый Экструдер Из Pp...