Adhering to the principle of "quality, service, efficiency and growth", we have gained trusts and praises from domestic and international client for

Plastic Extruder Machine For Sale

, Rubber Extruder

, Plastic Pipe Production Line

, Our main objectives are to deliver our consumers worldwide with high quality, competitive selling price, satisfied delivery and outstanding providers.

New Delivery for Eva Sheet Making Machine -

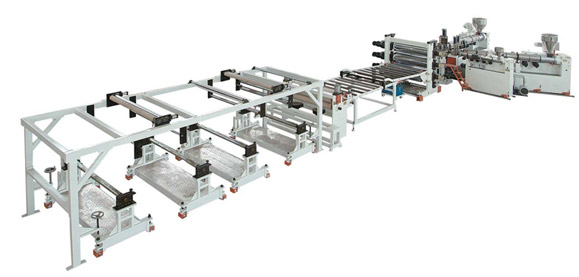

XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell Detail:

XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology)

With perfect closed alveolate construction, XPS heat insulation plate is considered to be the best insulation material in the market. Granules from recycled EPS plate, as the main material, go through the die foaming extruder, calibrator, haul-off and cutting unit. With lower density,water absorption,thermal conductivity and vapour penetrability than of other kinds of heat insolution plates, XPS heat insulation plate features with high strength, low wight, airtightness, corrosion resistance, aging resistance and low cost. Therefore this plate can be widely used in house insulation system,in cold storage、camps、barns and civil constructions, in ground constructions of airport raceway and square, in road and railway engineering constructions,in heat insulation system of apartments,office

buildings and workshops.

XPS heat insulation plate extrusion line has two types: single screw tandem extruders type and co-rotation parallel twin screw extruder with single screw extruder.The models are: 135/150 single screw tandem extruder type and 75/150 co-rotation parallel twin screw extruder with single screw extruder.Because of high mixing efficiency, co-rotation twin screw etruder

can process material of different components.

Newly forming machine designed by Jwell, adapting CO2 as forming agent, which is for taking palce of freon and butane , features of green environment protection and low cost consumption.

Product detail pictures:

Related Product Guide:

Guill introduces single-point concentricity extrusion tooling | Screw Extruder Machine

Medical Tubing Packaging Market Research Report by QYResearch.us | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

We are also focusing on improving the stuff management and QC system so that we could keep great advantage in the fiercely-competitive business for

New Delivery for Eva Sheet Making Machine -

XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell, The product will supply to all over the world, such as: Las Vegas

, Paraguay

, Slovakia

, Our company always concentrate on the development of the international market. We now have a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.