OEM China Water Pipe Twin Screw Extruder - JWE Co-rotation Parallel Twin-screw Pelletizing Machine – Jwell Detail:

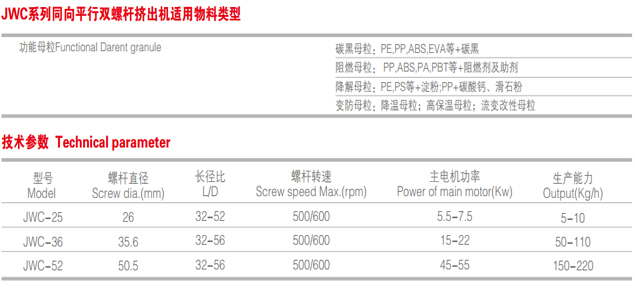

JWE Co-rotation Parallel Twin-screw Pelletizing Machine

Product detail pictures:

Related Product Guide:

Bandera ships fourth PET Rigid Film Extrusion Lines to Flight Plastics Group, New Zealand | Extruded Plastic Tubing

Twin Screw Extruders Market 2023 by Opportunities, Restraints Product, Key Developments, Overview and Forecast | Extruded Plastic Tubing

We have the most advanced production equipment, experienced and qualified engineers and workers, recognized quality control systems and a friendly professional sales team pre/after-sales support for OEM China Water Pipe Twin Screw Extruder - JWE Co-rotation Parallel Twin-screw Pelletizing Machine – Jwell, The product will supply to all over the world, such as: Canada , Jamaica , Mexico , Each product is carefully made, it will make you satisfied. Our merchandise in the production process have got strictly monitored, because it is only to supply you the best quality, we'll feel confident. High production costs but low prices for our long-term cooperation. You can have a variety choices and the value of all types are same reliable. If you have any question, do not hesitate to ask us.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.

-

PriceList for Двухшнековая Экструдер Анимация -...

-

Wholesale Price China Newly Design Straw Making...

-

Chinese wholesale Экструзионная Линия Для Напол...

-

Top Quality High Performance Recycled Polycarbo...

-

China Cheap price Extrusion Machine Parts - V...

-

Popular Design for Wpc Double Screw Extruder - ...