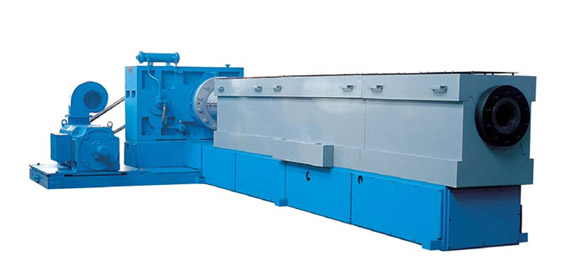

OEM Factory for Waste Recycling Plant - Film Die Series – Jwell Detail:

Film Die Series

Product detail pictures:

Related Product Guide:

Global Plastics Extrusion Market CAGR 2018 – Swot Analysis, Porters Five Forces Analysis, Forecast Till 2023 | Производственная Линия Ppr

Черномортранснефть может эксплуатировать НПС Заречье до 2024 г | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

We are also focusing on enhancing the things administration and QC program in order that we could keep fantastic advantage within the fiercely-competitive enterprise for OEM Factory for Waste Recycling Plant - Film Die Series – Jwell, The product will supply to all over the world, such as: Swedish , Irish , Puerto Rico , Over the years, with high-quality products, first- class service, ultra-low prices we win thee trust and favor of customers. Nowadays our products sell all over the domestic and abroad. Thanks for the regular and new customers support. We provide high quality product and competitive price, welcome the regular and new customers cooperate with us!

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.

-

Reliable Supplier China Reinforced Ppr Pipe Ext...

-

Hot Sale for Принцип Работы Двухшнекового Экстр...

-

100% Original Polystyrene Frame Moulding - Sma...

-

Factory Promotional Extrusion Machine Cost - S...

-

Cheapest Factory Strips Extruder Pet Strap Prod...

-

Factory Promotional Mini Twin Screw Extruder - ...