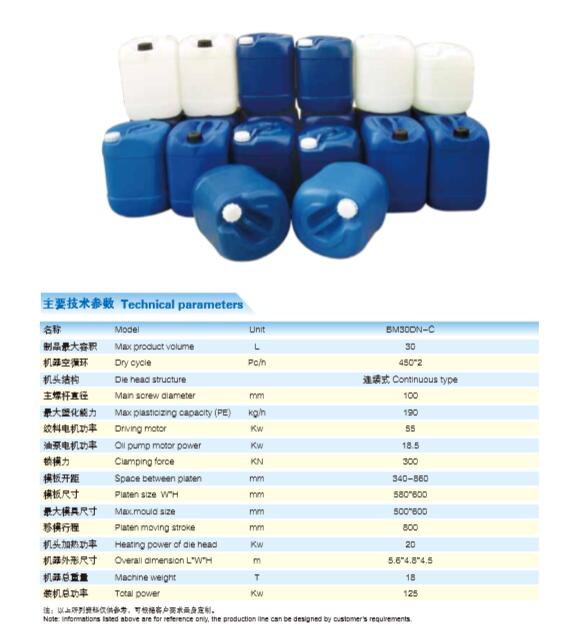

OEM manufacturer Mini Plastic Extrusion Machine - JWZ-BM30DN-C Blow Molding Machine – Jwell Detail:

JWZ-BM30DN-C Blow Molding Machine

Product detail pictures:

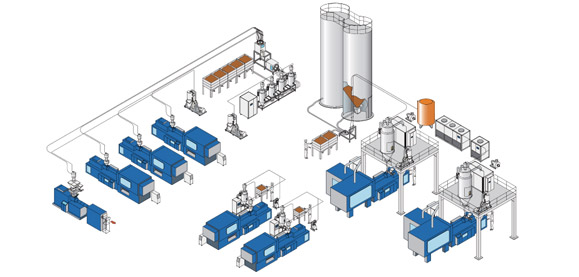

Related Product Guide:

Global Conical Twin Screw Extruder Market 2018 – Zhangjiagang Xinweier, Esde, Battenfeld-Cincinnati, Toshiba Machine | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

Правовое и нормативное регулирование ремонта основных средств | Производственная Линия Ppr

We support our buyers with ideal high quality products and high level service. Becoming the specialist manufacturer in this sector, we have gained rich practical experience in producing and managing for OEM manufacturer Mini Plastic Extrusion Machine - JWZ-BM30DN-C Blow Molding Machine – Jwell, The product will supply to all over the world, such as: Armenia , Australia , Qatar , Our professional engineering group will always be ready to serve you for consultation and feedback. We are able to also offer you with absolutely free samples to meet your requirements. Finest efforts will likely be produced to give you the ideal service and goods. For anyone who is thinking about our company and merchandise, please contact us by sending us emails or contact us quickly. As a way to know our merchandise and firm. lot more, you can come to our factory to find out it. We'll always welcome guests from all over the world to our business to build company relations with us. Please feel free to get in touch with us for business and we believe we are going to share the top trading practical experience with all our merchants.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!

-

Discountable price Extruder Spare Parts - Feed...

-

Low price for Window Upvc Profile - JWE Co-rot...

-

Factory supplied Трубопроводная Линия - Conica...

-

Wholesale Dealers of Pe Foam Extrusion Line - ...

-

Leading Manufacturer for 30mm Single Screw Extr...

-

Trending Products Self-cleaning Double Plate Sc...