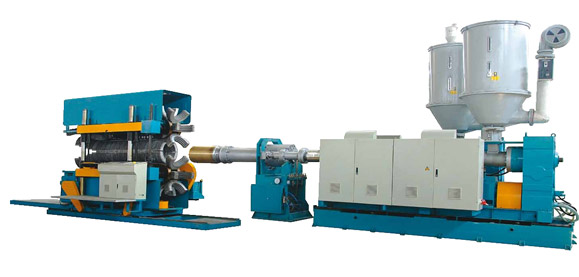

OEM Supply What Is Twin Screw Extruder - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell Detail:

XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology)

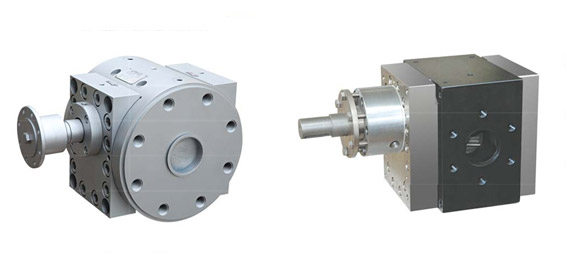

Product detail pictures:

Related Product Guide:

Очерский машиностроительный завод активно модернизирует мощности по производству нефтепромыслового оборудования // В тренде // Новости | Extruded Plastic Tubing

Extrusion Machinery Sales Market Forecast – Industry Value, Market Size, Top Companies and General Trends for 2018-2025 | Производственная Линия Ppr

continue to improve, to ensure product quality in line with market and customer standard requirements. Our company has a quality assurance system have been established for OEM Supply What Is Twin Screw Extruder - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell, The product will supply to all over the world, such as: Kyrgyzstan , Berlin , India , With many years good service and development, we have a qualified international trade sales team. Our goods have exported to North America, Europe, Japan, Korea, Australia, New Zealand, Russia and other countries. Looking forward to build up a good and long term cooperation with you in coming future!

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!

-

Factory wholesale Casement Door Profile - Sili...

-

Factory Price For Pp Sheet Extrusion Line - AP...

-

Chinese Professional rotating Twin Screw Extrud...

-

Cheap PriceList for Двухвинтовая Машина - PVC ...

-

Hot New Products Производитель На Двухшнековые ...

-

Factory directly supply Конструкция Экструзионн...