OEM/ODM China Plastic Window Profile - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell Detail:

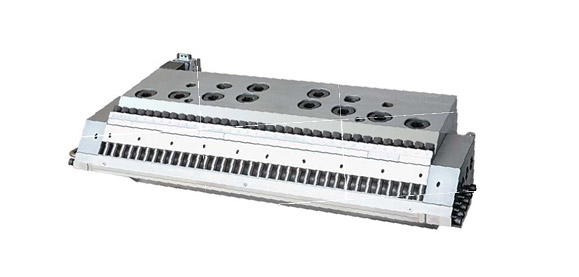

XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology)

Product detail pictures:

Related Product Guide:

MedAccred adds plastic extrusion to audit criteria | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

Call for Papers: Extrusion 2019: Plastics Technology | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

We have now numerous great personnel members good at advertising, QC, and working with kinds of troublesome dilemma from the creation course of action for OEM/ODM China Plastic Window Profile - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell, The product will supply to all over the world, such as: Namibia , Nigeria , Rwanda , We are your reliable partner in the international markets of our products. We focus on providing service for our clients as a key element in strengthening our long-term relationships. The continual availability of high grade products in combination with our excellent pre- and after-sales service ensures strong competitiveness in an increasingly globalized market. We are willing to cooperate with business friends from at home and abroad, to create a great future. Welcome to Visit our factory. Looking forward to have win-win cooperation with you.

We have been looking for a professional and responsible supplier, and now we find it.

-

Factory wholesale Модель Винтовые Изделия - PP...

-

Factory Cheap Hot Pvc Extrusion Line - Single ...

-

OEM Manufacturer Pvc Foam Extrusion - Sheet Di...

-

Wholesale Price Пластиковые Экструзионные Голов...

-

High Performance Pvc Pipe Extrusion Die Design ...

-

High Quality Vinyl Shutter Parts - DYQX Series...