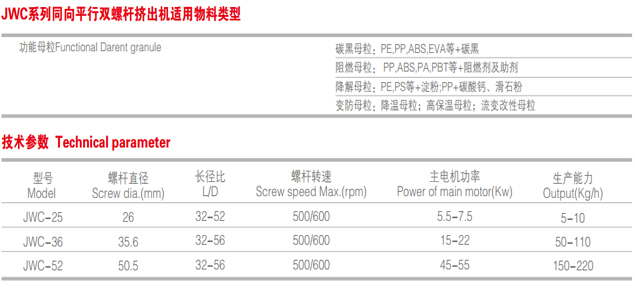

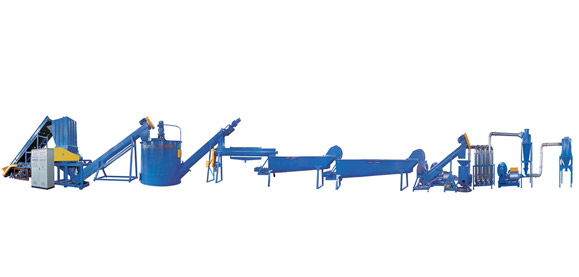

OEM/ODM Supplier Twin Screw Extruder Parts - JWE Co-rotation Parallel Twin-screw Pelletizing Machine – Jwell Detail:

JWE Co-rotation Parallel Twin-screw Pelletizing Machine

Product detail pictures:

Related Product Guide:

Global Medical Plastics Extrusion Market CAGR Estimated Range 2018 To 2023 With SWOT Analysis | Extruded Plastic Tubing

На Чебоксарской ГЭС проведут капремонт и замену релейной защиты блочного трансформатора // Гидроэнергетика // Новости | Производственная Линия Ppr

Our company sticks into the basic principle of "Quality is definitely the life of the business, and status may be the soul of it" for OEM/ODM Supplier Twin Screw Extruder Parts - JWE Co-rotation Parallel Twin-screw Pelletizing Machine – Jwell, The product will supply to all over the world, such as: Cyprus , New Delhi , Egypt , We have a dedicated and aggressive sales team, and many branches, catering to our main customers. We are looking for long-term business partnerships, and ensure our suppliers that they will definitely benefit in both short and long run.

This is a very professional wholesaler, we always come to their company for procurement, good quality and cheap.

-

Quality Inspection for Designer Unique Waste Pv...

-

Ordinary Discount Rubber Extruders - JWZ-BM30/...

-

Hot Selling for Cheap Plastic Extruder - DYQT ...

-

Well-designed Extruding Plastic Garbage Bag Mac...

-

Massive Selection for Pvc Window Sill Panel Pro...

-

China Supplier Pe-wpc Conical Twin Screw Extrud...