Original Factory Polypropylene Yarn Extruder Machine - Industrial Roller – Jwell Detail:

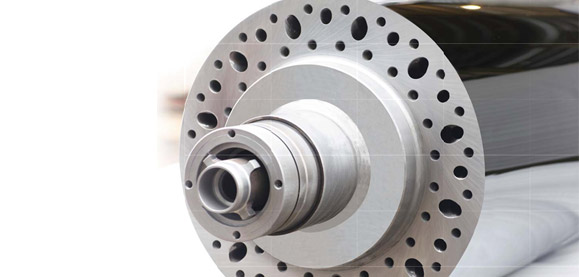

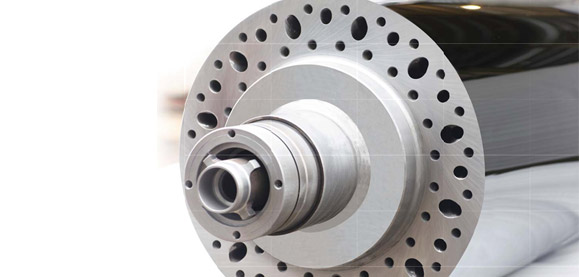

Industrial Roller

Product detail pictures:

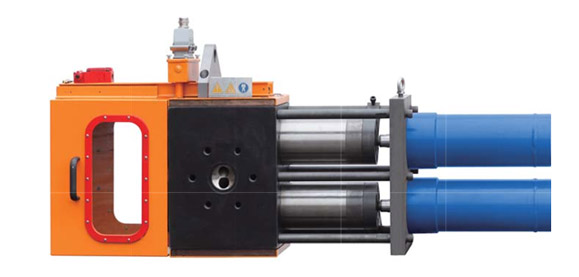

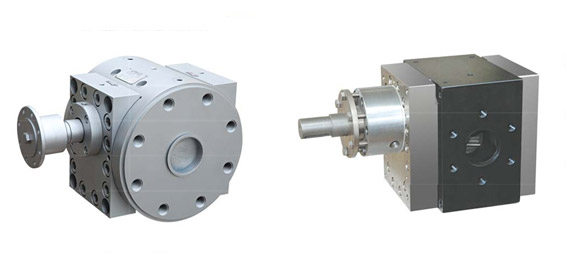

Related Product Guide:

Extruders and Compounding Machines Market by top Key Vendors, Trends, Sales, Supply, Demand, Analysis and Forecasts to 2025 | Wpc Extrusion Machine

Global Plastics Extrusion Market CAGR 2018 – Swot Analysis, Porters Five Forces Analysis, Forecast Till 2023 | Screw Extruder Machine

Our well-equipped facilities and exceptional good quality manage throughout all stages of production enables us to guarantee total shopper satisfaction for Original Factory Polypropylene Yarn Extruder Machine - Industrial Roller – Jwell, The product will supply to all over the world, such as: Canberra , Swiss , Comoros , Based on our guiding principle of quality is the key to development, we continually strive to exceed our customers' expectations. As such, we sincerely invite all interested companies to contact us for future cooperation, We welcome old and new customers to hold hands together for exploring and developing; For more information, be sure to feel free to contact us. Thanks. Advanced equipment, strict quality control, customer-orientation service, initiative summary and improvement of defects and extensive industry experience enable us to guarantee more customer satisfaction and reputation which, in return, brings us more orders and benefits. If you are interested in any of our merchandise, make sure you feel free to contact us. Inquiry or visit to our company are warmly welcome. We sincerely hope to start a win-win and friendly partnership with you. You can see more details in our website.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.

-

Manufacturer of Plastic Sheet Extruder Machine ...

-

Europe style for Honeycomb Ceramics - PVC Homo...

-

Hot New Products Давление Экструдера - JWP Ser...

-

PriceList for Линия Экструзии Листов Из Пвх - ...

-

Hot New Products Bubble Film Wrap Machine - JW...

-

High Quality for Pvc Extruder Machine - DYPS-Z...