PriceList for Side Feeder Twin Screw Extruder - Hollow Cross Section Plate Die Series – Jwell Detail:

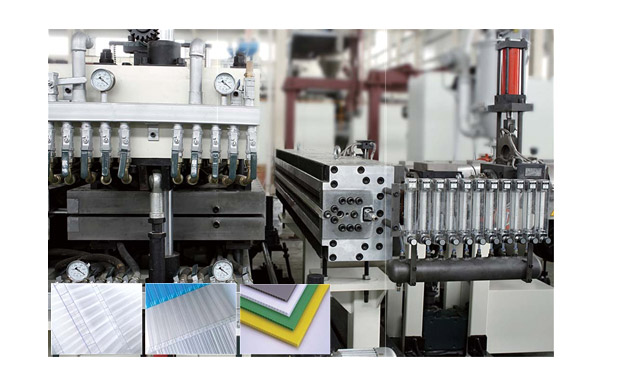

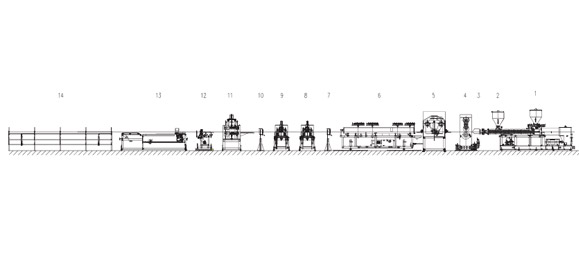

Hollow Cross Section Plate Die Series

Product detail pictures:

Related Product Guide:

Booms and Busts in Twin-screw Extruders Market | Data Includes Research News | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

Former American Kuhne employees form new single-screw extruder company | Производственная Линия Ppr

Our pros are lessen prices,dynamic sales team,specialised QC,sturdy factories,top quality services and products for PriceList for Side Feeder Twin Screw Extruder - Hollow Cross Section Plate Die Series – Jwell, The product will supply to all over the world, such as: South Africa , Miami , US , "Make the women more attractive "is our sales philosophy. "Being customers' trusted and preferred brand supplier" is the goal of our company. We are strict with every part of our work. We sincerely welcome friends to negotiate business and start cooperation. We hope to join hands with friends in different industries to create a brilliant future.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!

-

18 Years Factory Loss In Weight Feeder For Extr...

-

OEM China Polyolefins Solid Wall Pipe Extrusion...

-

Hot sale Factory Tube Extrusion - Narrow Gap C...

-

China Gold Supplier for Pvc Extruder Screw And ...

-

Good Wholesale Vendors Pvc Coil Mat Making Mach...

-

OEM Manufacturer Pvc Profiles In Plastic Profil...