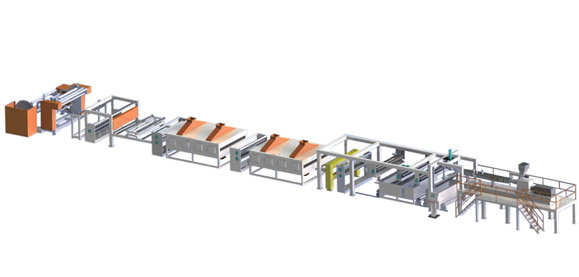

Professional Design Plastic Extrusion/ Plant/equipment/machinery - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell Detail:

XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology)

Product detail pictures:

Related Product Guide:

Global Twin-Screw Extruder market 2018 Provides an In-Depth Insight of Sales Analysis | Производственная Линия Ppr

Benk Machine Set to Test Two Sets of PVC Pipe Machines in Their Factory – Press Release | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

Sticking for the principle of "Super Quality, Satisfactory service" ,We have been striving for being a superb small business partner of you for Professional Design Plastic Extrusion/ Plant/equipment/machinery - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell, The product will supply to all over the world, such as: Barbados , Birmingham , Madagascar , Our qualified engineering team will usually be prepared to serve you for consultation and feedback. We've been able to also deliver you with absolutely free samples to meet your needs. Best efforts might be made to offer you the ideal service and items. For anyone who is interested in our company and products, be sure to make contact with us by sending us emails or contact us right away. In order to know our solutions and organization. ar more, you can come to our factory to determine it. We are about to usually welcome guests from around the globe to our corporation. o create small business relations with us. Please genuinely feel no cost to speak to us for enterprise. nd we believe we have been gonna share the most effective trading practical experience with all our merchants.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!

-

Factory Promotional Пластиковые Экструдеры - P...

-

New Fashion Design for Wenger Extruder Machine ...

-

Good Wholesale Vendors Building Plastic Profile...

-

Factory supplied Small Plastic Extruders For Sa...

-

Cheapest Price Pp Pe Screw And Barrel - UPVC P...

-

Factory directly supply Single Hole Extruder Sc...