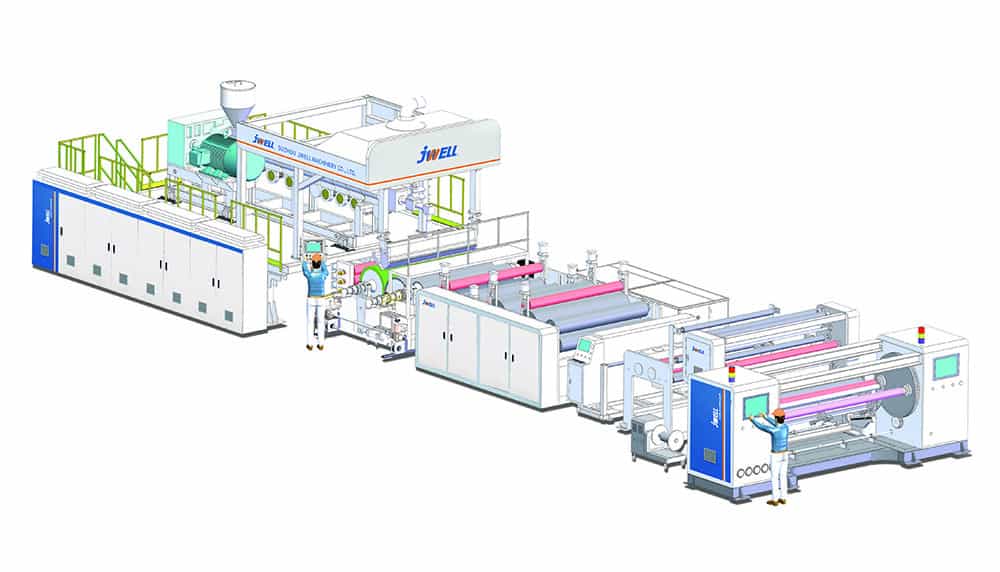

PVB EVA POE cast film extrusion line

Short Description:

product description our certificates FAQ request a quote Menu product description our certificates FAQ request a quote PVB film extrusion line PVB film is a thermo-plastic film made of PVB resin and plasticizer. PVB film extrusion line is widely used for interlayer of construction glass, automobile, Solar photovoltaic glass, bullet-proof glass, sound proof glass, etc. Features high safety, sound proof, ultraviolet-proof, and it can be colorful or super...

Product Detail

Product Tags

PVB film extrusion line

PVB film is a thermo-plastic film made of PVB resin and plasticizer.

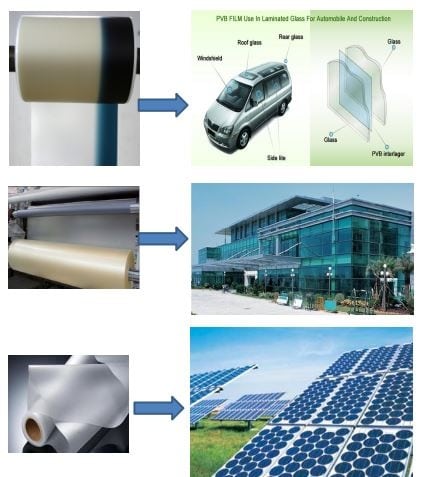

PVB film extrusion line is widely used for interlayer of construction glass, automobile, Solar photovoltaic glass, bullet-proof glass, sound proof glass, etc.

Features high safety, sound proof, ultraviolet-proof, and it can be colorful or super transparent, and used for construction wall glass for more than 70 years. Also it is of Optical application value, and it is used for solar photovoltaic as well.

There are two types of production method: by roller forming and water cooling forming, the thickness of final product will be 0.38-1.52mm, width will be 500-3400mm, transparent, color strip and full color film are optional.

PVB film extrusion line Main technical parameter

| Model | Products width(mm) | Products thickness(mm) | Designed line speed(m/min) | Capacity(kg/h) |

| JWS150 | 2000 | 0.38-1.52 | 10 | 400 |

| JWE95-JWE65 | 2500 | 0.38-1.52 | 10 | 600 |

| JWE135- JWE95 | 3400 | 0.38-1.52 | 20 | 1200 |

PVB film extrusion line Applicaiton

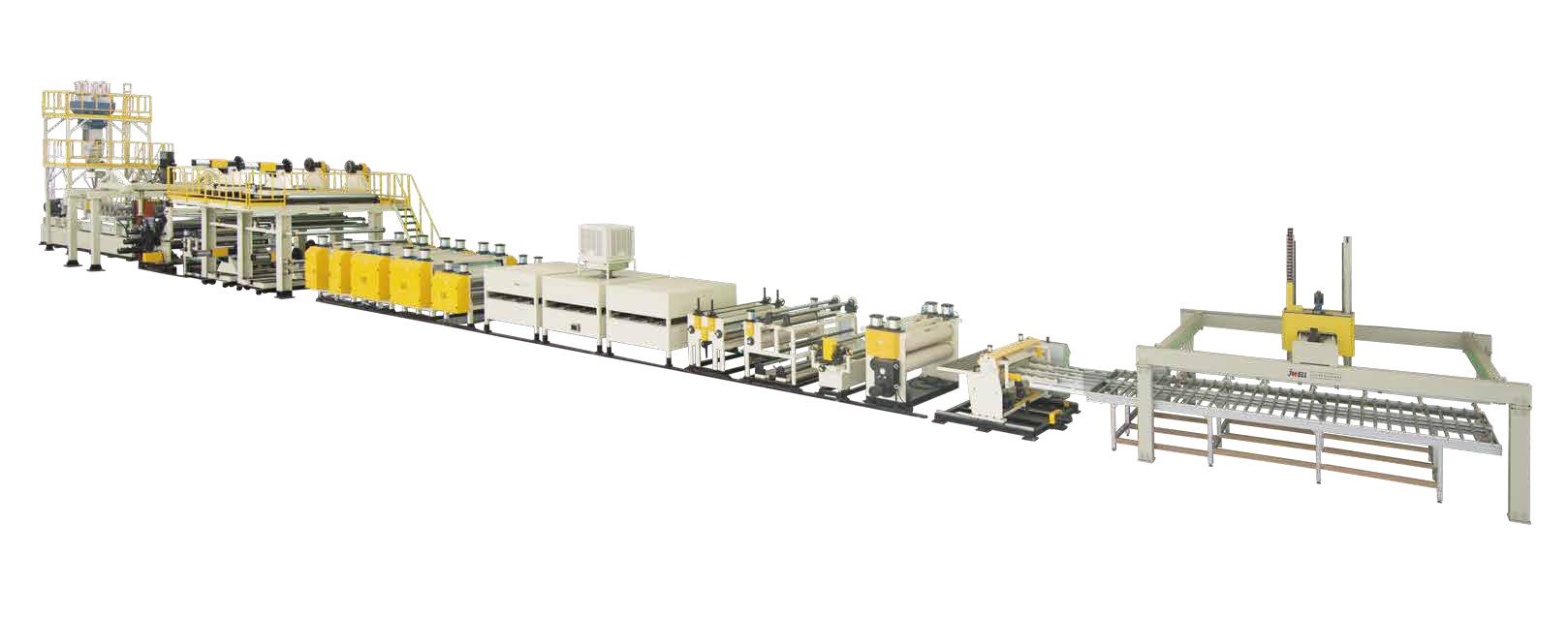

EVA/POE solar Film Extrusion Line

EVA solar film extrusion line:

Automatic gravimetric feeding system makes sure variety of solid, liquid additives and raw materials high-precision feeding.

Low-temperature extrusion systems to ensure adequate mixing in the premise of plastination to prevent crosslinking additives.Special design of Casting part give the perfect solution to roller adhibition and water spalling.

Special online tempering device to get rid of inner stress. Tension control system ensure the flexible sheets conveying placidly during cooling , pulling andwinding process.

The on-line thickness measuring and defect inspecting system can provide real-time feedback of the production quality of EVA solar film.

EVA/POE solar Film Extrusion Line advantage editing

- High transparency and high adhesion can be applied to various interfaces, including glass, metal and plastics such as PET.

- Good durability can resist high temperature, moisture, uv and so on.

- Easy storage. When stored at room temperature, EVA’s adhesion is not affected by humidity and water absorbent film.

- Compared with PVB, it has stronger sound insulation effect, especially high frequency sound effect.

- Low melting point, easy flow, applicable to all kinds of glass laminating processes, such as embossed glass, tempered glass, bent glass, etc.

Product performance editing

EVA film is used as laminated glass, which fully complies with the national standard of laminated glass, gb9962-99. Take 0.38mm thick transparent film as an example, and the performance indicators are as follows:

Project indicators project indicators

Tensile strength (MPa) = 17 visible light transmittance (%) = 87 fracture elongation (%) = 650 fog rate (%) 0.6

The bonding strength (kg/cm) is greater than or equal to 2 irradiation resistant qualified water absorption rate (%) is less than or equal to 0.15

Qualified heat resistance, qualified moisture resistance, qualified shock resistance, qualified pellet bag impact performance, qualified uv cutoff rate of 98.5%

Production equipment editor

Will make good glass vacuum bag vacuum, vacuum 700 MMHG or higher (0.092 Mpa), the temperature is 100-110 ℃ (glass surface temperature), heat preservation for 10 minutes, cooling below 60 ℃, discharge vacuum.

Because of the material characteristics of EVA, there are very high requirements when EVA is processed and shaped. According to its strict requirements on solar cell life and anti-aging, many domestic manufacturers have made great progress in formula after repeated tests.

And most of the domestic EVA film has reached the international advanced level (all indicators meet the requirements, some indicators exceed foreign products).

Due to the stringent requirements of the photovoltaic industry, the requirements for EVA production equipment are also very high.

The stability of the equipment, and the control of the shrinkage rate, as little as possible to affect the loss of formula components. The domestic manufacturer that makes film equipment has a lot of, but more or less cannot achieve the requirement.

As a result, many EVA manufacturers choose to assemble or assemble their own equipment. Until 2010, there was a whole production enterprise of EVA film production line in China (suzhou jinweier machinery co., LTD.).

China’s growth in the EVA industry has been even faster. The cost of EVA film is reduced, and the cost of pv industry is reduced indirectly.

Storage condition editing

When storage don’t take out, put them in the original packaging a cool ventilated place, and temperature not to exceed 30 ℃, humidity is below 80%.

Product specification editor

Thickness: 0.25mm, 0.38mm width: 2.1m 6. Various colors (transparent, opaque and color) are available.

Nowadays, EVA is more used in the field of solar pv, as the encapsulated film of photovoltaic modules.

Mainly use foreign original product, with today’s increasing ability of the independent research and development production, domestic products have gradually revealed and new materials such as chemistry, Chinese academy affiliated Chen, zhejiang has FIRST (foster) and hangzhou compro, etc.

Use notes to edit

- curing conditions: fast type of film, heating to 135 ~ 135 ℃, temperature 15 ~ 20 min; Conventional type of film, heated to 145 ℃, the constant temperature for 30 min.

- Transmittance: over 90%.

- Crosslinking degree: the quick-curing adhesive film is more than 70%, and the conventional adhesive film is more than 75%.

- Peel strength: glass/film is greater than 30N/cm, TPT/ film is greater than 20N/cm.

- temperature resistance, high temperature 85 ℃, 40 ℃, low temperature – do not heat bilges cold shrink, good dimensional stability.

- Uv aging resistance: no cracking or aging due to prolonged exposure to uv rays.

Notes editing

In the process of using, attention should be paid to prevent moisture and dust, avoid contact with colored objects; Do not expose the whole roll of film without the outer package to air; If the sliced film can not be used up in the same day, cover tightly.

If EVA film absorbs moisture, it will affect the adhesion of glass. If the dust is absorbed, the transmittance will be affected. If it comes into contact with colored and unclean objects, it is easy to be polluted due to the strong adsorption capacity of EVA film.

Marketing status editor

Global supply of EVA film presents a few companies dominated the competitive landscape, market share higher four EVA film companies, respectively is the STR (STR), Japan’s mitsui chemical, bridgestone and hangzhou foster, four in total global market share more than 80% of the EVA film.

STR has three factories in the United States, Spain and Malaysia. By the end of November, its EVA film production capacity had reached 150 million square meters. Mitsui chemical is an old giant in Japan.

The newly built EVA factory has been put into production, its resin capacity has reached 50,000 tons/year, and the EVA film capacity has reached 100 million square meters. Hangzhou foster is the largest pv EVA film manufacturer in China, and its production capacity reached 150 million square meters by the end of 2011.

According to 35 gw solar module production capacity calculation in the whole year of 2012, the area of about 490 million square meters of EVA film required, and statistics to the mainstream factory production capacity is about 557 million square meters, relative to other solar industry chain link, EVA film output and basic matching production capacity, and affected by excess capacity is not serious.

The solar cell output accounting for about 60% global share in our country, according to the global shipments of 35 gw calculation, the solar cell output approximately 20 gw, corresponding EVA demand of about 280 million square meters, the domestic largest EVA film producers foster output of about 158 million square meters, is expected to domestic components manufacturing enterprises still have 100 million square meters of EVA film depends on import, occupy about 30% of the proportion, the domestic production enterprises EVA foster, icahn science and technology, such as red polaroid, there is still a large space to grow up.

The whole, the global EVA film production capacity and the actual demand for basic match, in the short term, new entrants to the enterprise is less, the increase of the pv module shipments, predict the future will further increase the demand for EVA film, EVA film manufacturers will further expand production capacity, there will be a structural adjustment.

2007 global pv systems installed capacity of 2826 mw, rose 62% in 2006, the solar cell output of 3436 mw, a 56% increase over 2006, the Chinese solar cell production global market share increased to 35%, and for the first time more than the Japanese (share of 26%), the first in the world.

Domestic demand in 2009 solar cell EVA film of 120 million square meters, and EVA film at home and abroad, the existing production capacity of only 50 million square meters, is unable to meet the demand of domestic battery manufacturers, while existing manufacturers in product quality than there is a certain gap with foreign products, but has absolute cost advantages, mainly supply for small and medium-sized enterprises, is also in short supply. Well-known solar cell manufacturers need to import the film mainly.

EVA/POE solar Film Extrusion Line Main technical parameter

| Model | Production width | Production thickness | Capacity |

| JWS130-1200 | 810mm | 0.2-0.8mm | 250kg/h |

| JWS150-2400 | 2200mm | 0.2-0.8mm | 400kg/h |

EVA/POE solar Film Extrusion Line Application

FAQ

- International Commercial Terms(Incoterms): FOB, CFR, CIF, EXW

- Terms of Payment: LC, T/T

- Average Lead Time: Peak season lead time: 3-6 months, Off season lead time: 1-3 months

- Number of Foreign Trading Staff:>50 People

Yes, We own 5 manufacturing bases and sales center in Shanghai , Suzhou ,Changzhou, Zhou Shan, Dongguan China.

Jwell made the first Chinese screw and barrel in 1978 in brand name Jinhailuo.After more than 40 years development,

JWELL is one of the biggest extrusion machine supplier in China with 300design&test engineer, 3000 employees.

Jwell has become the premier supplier of extrusion lines and reliable business partners. Welcome to drop in us.

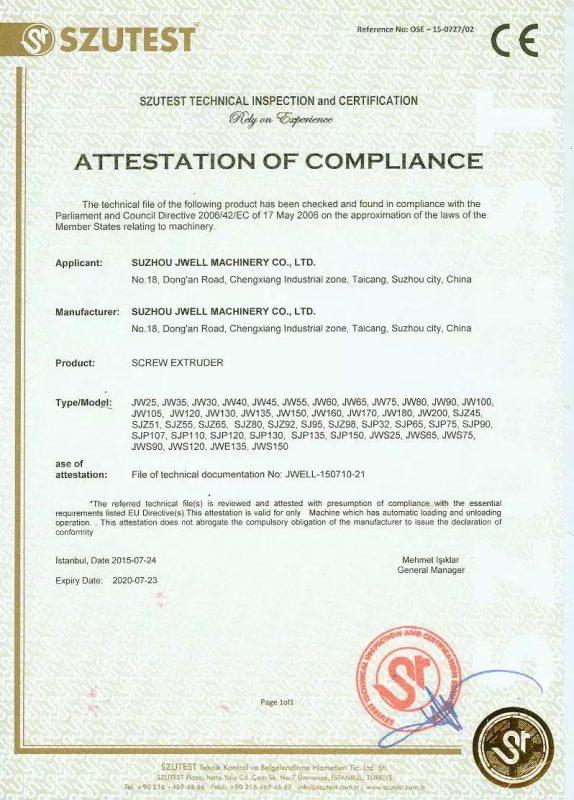

Our machines taking the European standards and follow the Germany type of business, we cooperation with

International famous brands Siemens Schneider Flender Omron ABB WEG Falk Fuji etc. Our company continuously

imports over 1000 international first-class high precision processing equipment such as multistage machining centers, CNC lathes and CNC milling machines from Korea, Japan etc. All our processes strictly adhere to CE certification,

IS09001 and 2008 quality management system . And we have 12 months quality warranty time. We testing the

machine performances before each delivery. Jwell service engineers will always be here for anything you needed.

Usually it takes about 1 – 4 months depends on different machinery upon receipt of order advance payment.

Once clear your requirements and determined extrusion line is ideal for you. We will send technical solutions and

Proforma Invoice to you. You can pay via TT bank transfer, LC as you like.

One. We provide both customized extrusion lines and technical solutions. Welcome contact with us for technical

innovation or improvements for your future purchasing plan.

We produce more than 2000 advanced extrusion lines every year world wide.

We can send the small spare parts by air express for urgent matter. And the complete production line by sea

to save the cost. You can either use your own assigned shipping agent or our cooperative forwarder. The nearest

port is China Shanghai, Ningbo port, which is convenient for maritime transportation..

Yes, we support our business partners by pre-after sale service. Jwell has more than 300 technical testing

engineers traveling world wide. Any cases would be responded with prompt solutions. We provide training, testing,

operation and maintenance service for a life time.

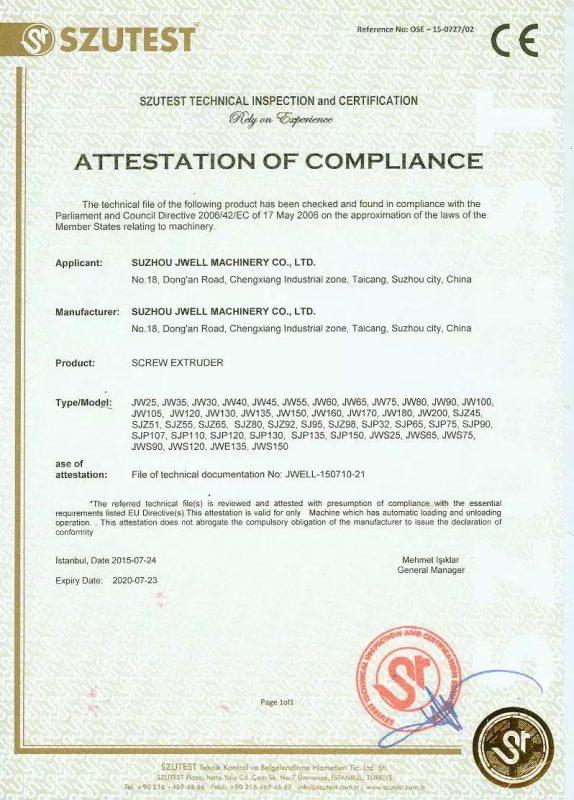

Certificates

Certified By:SGS

extrusion down stream equipment

Certified By:SGS

extrusion down stream equipment

Certified By:SGS

extrusion down stream equipment

Certified By:SGS

extrusion down stream equipment

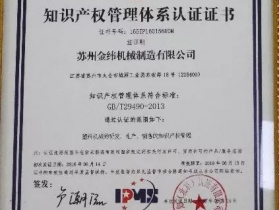

Certified By:Other

Design, Development, Manufacture and Sales of intellectual property rights management for Plastic Machine

Certified By:Other

Design, Development, Manufacture and Sales of Plastic Pipe and Sheet Extrusion Production Line

Certified By:Quality Austria Training, Certification and Evaluation Ltd

Plastic extrusion line