Short Lead Time for Винт Смешивания Maddock - Film Die Series – Jwell Detail:

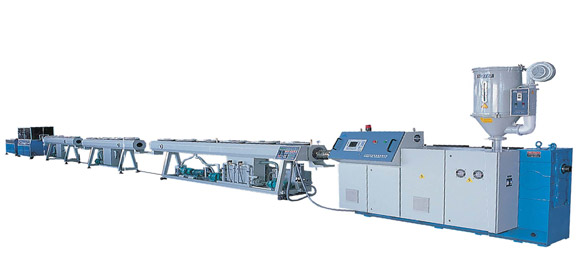

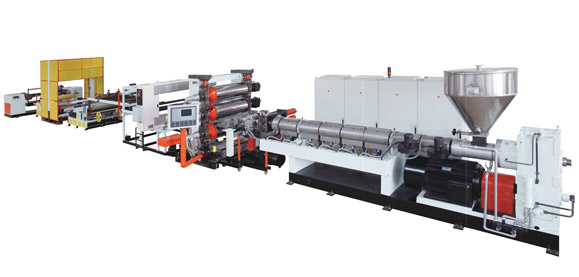

Film Die Series

Product detail pictures:

Related Product Guide:

Об изменениях в российском законодательстве в сфере электроэнергетики за 19-25 ноября / Статьи и обзоры / Элек.ру | Extruded Plastic Tubing

What You Can Learn From Pharma Compounders : Plastics Technology | Wpc Extrusion Machine

All we do is usually connected with our tenet " Customer to start with, Rely on initial, devoting on the food packaging and environmental protection for Short Lead Time for Винт Смешивания Maddock - Film Die Series – Jwell, The product will supply to all over the world, such as: Seattle , Leicester , California , Adhering to the principle of "Enterprising and Truth-Seeking, Preciseness and Unity", with technology as the core, our company continues to innovate, dedicated to providing you with the highest cost-effective products and meticulous after-sales service. We firmly believe that: we are outstanding as we are specialized.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.

-

Discountable price Barrel For Extruder - PS Fo...

-

OEM Manufacturer Plastic Geonet Extruder Machin...

-

Factory best selling Plastic Film Extruding Mac...

-

Short Lead Time for Twin Screw Extruder Pet Str...

-

factory Outlets for Screw Design For Plastic Ex...

-

factory Outlets for Pp Strapping Straps Machine...