Short Lead Time for Компаундирующая Экструзионная Машина - Biaxially Oriented Die – Jwell Detail:

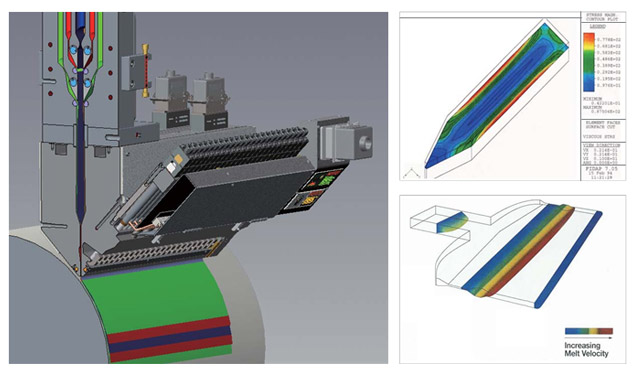

Biaxially Oriented Die

Product detail pictures:

Related Product Guide:

Extrusion specialist talks ‘core’ competencies in medical catheter manufacturing | Производственная Линия Ppr

Call for Papers: Extrusion 2019: Plastics Technology | Wpc Extrusion Machine

We persist with the principle of "quality 1st, assistance initially, continual improvement and innovation to meet the customers" for your management and "zero defect, zero complaints" as the standard objective. To great our service, we present the products and solutions while using the very good top quality at the reasonable cost for Short Lead Time for Компаундирующая Экструзионная Машина - Biaxially Oriented Die – Jwell, The product will supply to all over the world, such as: Liberia , Egypt , South Korea , Our company has a skillful sales team, strong economic foundation, great technical force, advanced equipment, complete testing means, and excellent after-sales services. Our items have beautiful appearance, fine workmanship and superior quality and win the unanimous approvals of the customers all over the world.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.

-

Wholesale U Channel Plastic Extrusion - Single...

-

China Supplier Pvc Profile Extrusion Dies - JW...

-

Manufacturing Companies for Pe Extruder - Sili...

-

Fixed Competitive Price Pe Tube Extruder Machin...

-

China Cheap price Plastic Extruded Tube - DYSS...

-

Quality Inspection for Cable Extruding Machiner...