Short Lead Time for Mixing Machine Price - Film Die Series – Jwell Detail:

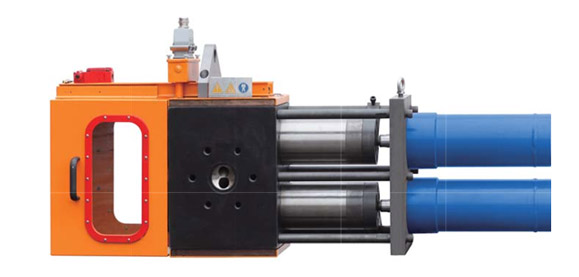

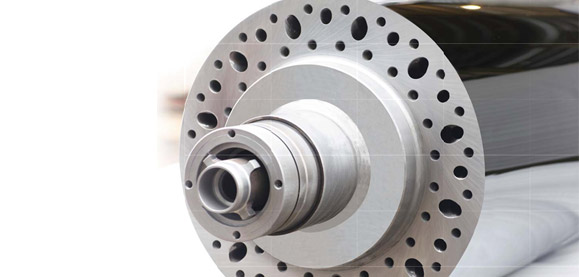

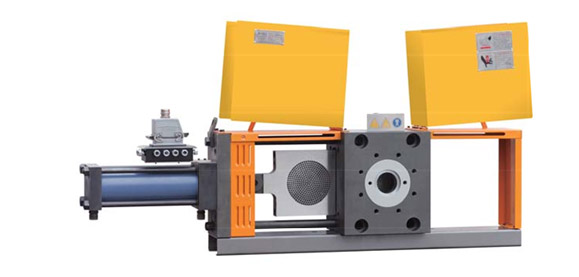

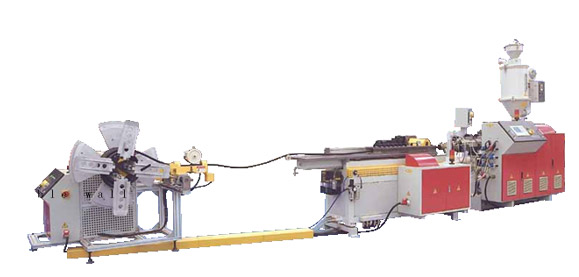

Film Die Series

Product detail pictures:

Related Product Guide:

На Московском нефтеперерабатывающем заводе завершена замена катализаторов технологических установок // В тренде // Новости | Screw Extruder Machine

American Securities Acquires CPM | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

Innovation, excellent and reliability are the core values of our firm. These principles today more than ever form the basis of our success as an internationally active mid-size corporation for Short Lead Time for Mixing Machine Price - Film Die Series – Jwell, The product will supply to all over the world, such as: Jeddah , Argentina , Turkey , Excellent quality comes from our adherence to every detail, and customer satisfaction comes from our sincere dedication. Relying on advanced technology and industry reputation of good cooperation, we try our best to provide more quality products and services to our customers, and all of us are willing to strengthen exchanges with domestic and foreign customers and sincere cooperation, to build a better future.

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.

-

Low MOQ for Pvc Door Panel Extrusion/Production...

-

Manufacturer of Used Plastic Extrusion Equipmen...

-

Factory source Pvc Foam Board Manufacturing Mac...

-

Good quality Plastic Extruder Machinery Supplie...

-

Super Purchasing for Pvc U Channel Profile Plas...

-

Factory Supply Plastic Pp Polypropylene Tape Ex...