Special Design for Single-screw Extruder Machine - Hollow Cross Section Plate Die Series – Jwell Detail:

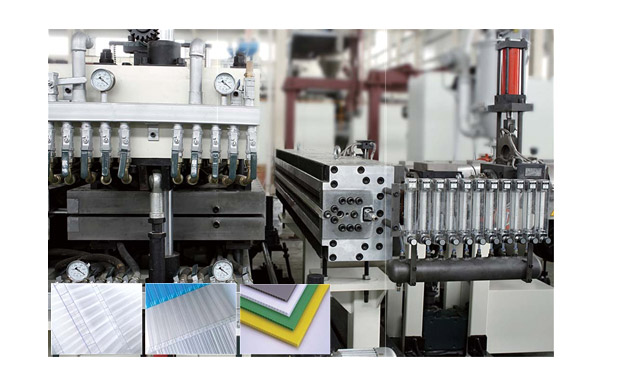

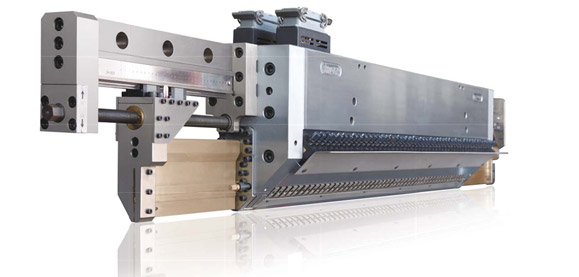

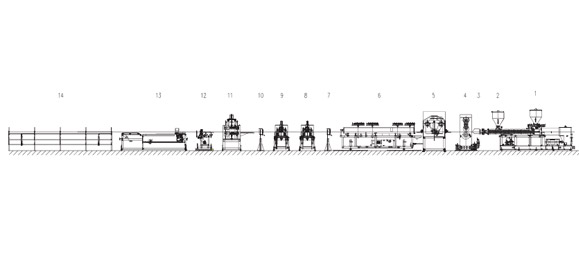

Hollow Cross Section Plate Die Series

Product detail pictures:

Related Product Guide:

Unique Advantages of Process Analytical Technology in Twin-Screw Granulation | Extruded Plastic Tubing

Global Plastic Extrusion Machinery Market 2018-2024 – Drivers, Restraints and Opportunities | Производственная Линия Ppr

Our company promises all users of the first-class products and the most satisfying post-sale service. We warmly welcome our regular and new customers to join us for Special Design for Single-screw Extruder Machine - Hollow Cross Section Plate Die Series – Jwell, The product will supply to all over the world, such as: Bulgaria , Netherlands , Amman, Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements. We can provided good quality with competitive price for you.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.

-

Good Quality Pe Pipe Single Screw Extruder - H...

-

Renewable Design for Lab Extruder Machine - Co...

-

China wholesale Hdpe Plastic Extrusion Profile ...

-

High Quality Vinyl Shutter Parts - DYQX Series...

-

One of Hottest for Parallel Extruder Design Bar...

-

2017 Latest Design Film Laminated Pvc Profile E...