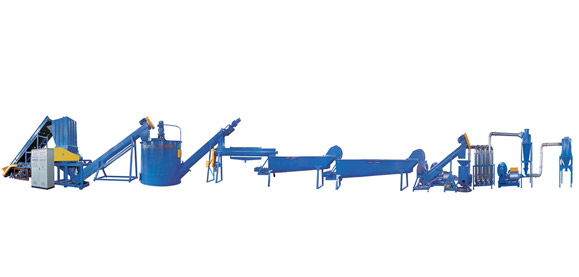

Trending Products Twin Screw Ldpe Extruder - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell Detail:

XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology)

Product detail pictures:

Related Product Guide:

Registration Opens for Extrusion 2018 Conference : Plastics Technology | Screw Extruder Machine

Global Medical Tubing Market 2018 Forecast to 2022 | Производственная Линия Ppr

The pretty loaded projects management experiences and one to a person support model make the high importance of business enterprise communication and our easy understanding of your expectations for Trending Products Twin Screw Ldpe Extruder - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell, The product will supply to all over the world, such as: Slovakia , United States , Kyrgyzstan , Adhering to the principle of "Enterprising and Truth-Seeking, Preciseness and Unity", with technology as the core, our company continues to innovate, dedicated to providing you with the highest cost-effective solutions and meticulous after-sales service. We firmly believe that: we're outstanding as we have been specialized.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.

-

Factory Promotional Wpc Extrusion Machine - La...

-

Good quality Конический Экструдер - Single Scr...

-

Professional China Extrusion Profile Pvc Profil...

-

100% Original Zipper Profile Extruder - Sheet ...

-

Factory selling Plastic Extrusion Equipment For...

-

Factory directly supply Expanded Twin Screw Ext...