Well-designed Wpc Floor Extruder - High-speed Film Coating Die Series – Jwell Detail:

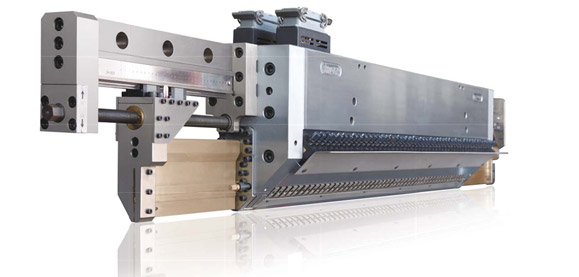

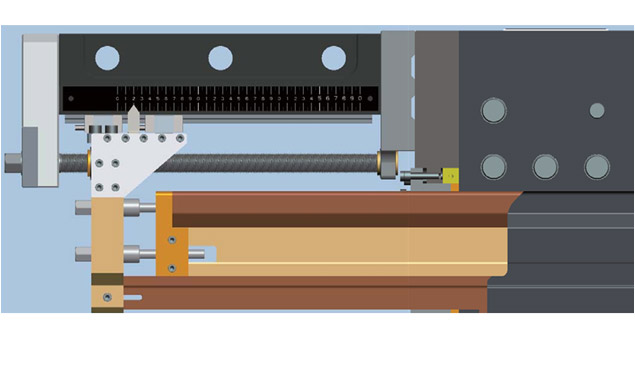

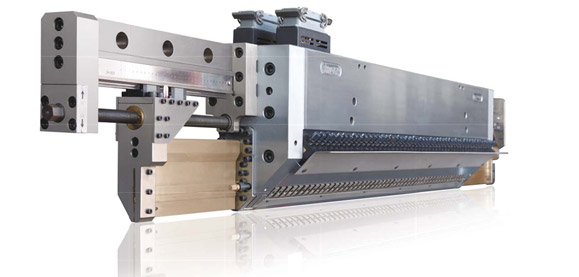

High-speed Film Coating Die Series

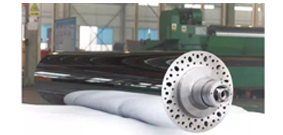

Product detail pictures:

Related Product Guide:

Trio of extruder enhancements showcased by battenfeld-cincinnati at NPE2018 | Wpc Extrusion Machine

Extruders and Compounding Machines Market by top Key Vendors, Trends, Sales, Supply, Demand, Analysis and Forecasts to 2025 | Производственная Линия Ppr

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Well-designed Wpc Floor Extruder - High-speed Film Coating Die Series – Jwell, The product will supply to all over the world, such as: Swansea , Birmingham , Bulgaria , We hope we can establish long-term cooperation with all of the customers. And hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need!

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!

-

Factory selling Cpvc Pipe Making Machine - Var...

-

Well-designed Used Plastic Extruder Machine - ...

-

High Quality Abs Filament Extruder - Screw and...

-

Leading Manufacturer for Extruder Machine Price...

-

Rapid Delivery for Pvc Foam Plastic Internal Ex...

-

Best Price on Plastic Pellet Extruder Machine -...