Other Special Pipe Production Line

Short Description:

product description our certificates FAQ request a quote Menu product description our certificates FAQ request a quote PP Ultra-quiet Drain Pipe Production Line PP ultra-quiet tube adopts two or three machines co-extruded to produce special sound-insulating viscoelastic material as the middle layer, which can adjust the density and microstructure of the pipe, absorb the audible and acoustic waves, prevent sound waves from passing out, and have better noise reductio...

Product Detail

Product Tags

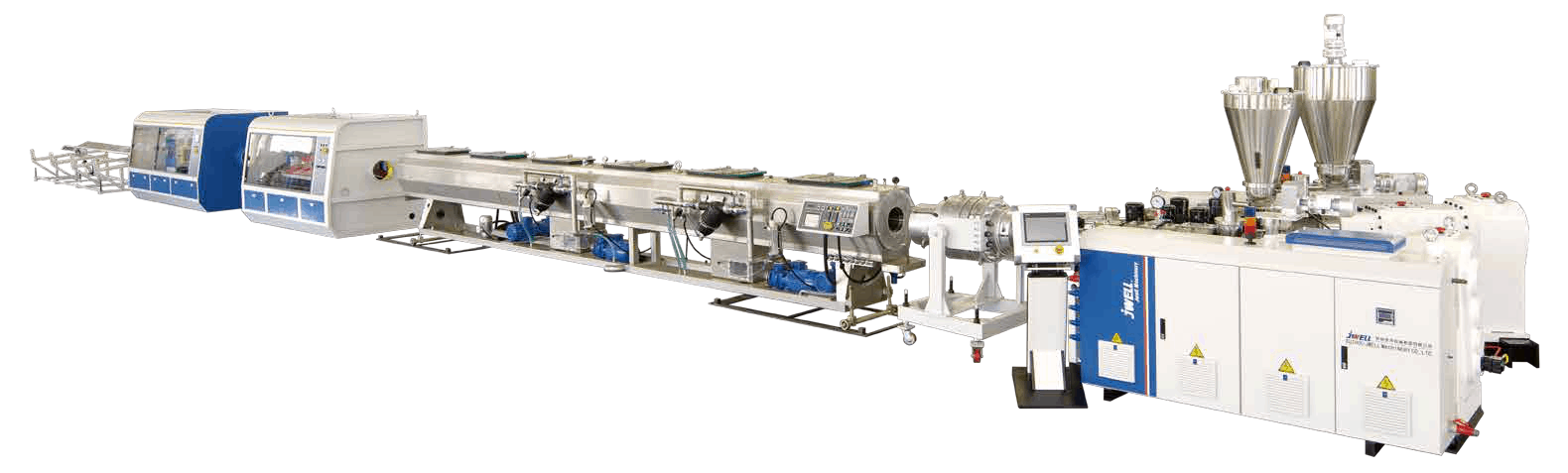

PP Ultra-quiet Drain Pipe Production Line

PP ultra-quiet tube adopts two or three machines co-extruded to produce special sound-insulating viscoelastic material as the middle layer, which can adjust the density and microstructure of the pipe, absorb the audible and acoustic waves, prevent sound waves from passing out, and have better noise reduction effect than the cast iron pipe. Polypropylene is non-toxic and can be reused many times.

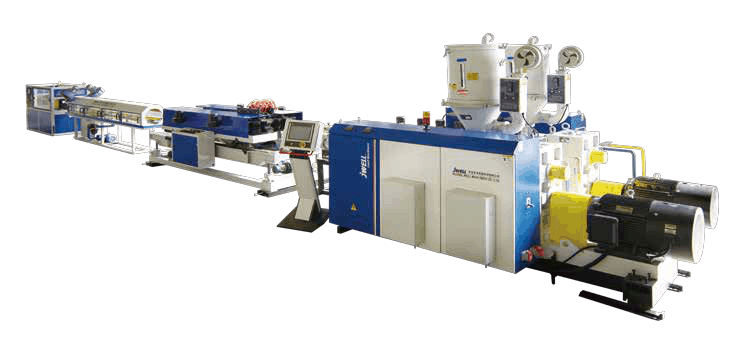

Steel Reinforce Spiral Pipe Extrusion Line

Steel reinforced spiral pipe extrusion line Steed reinforced pipe has the features of not easy in corrosion of the steel band, the top of the steel band has the thicker protection layer, reinforced rib is not easy in collapse, the seam is connected strongly, the tensile strength of the pipe in the axial direction is high so that during the use the pipe is not easy in leakage.

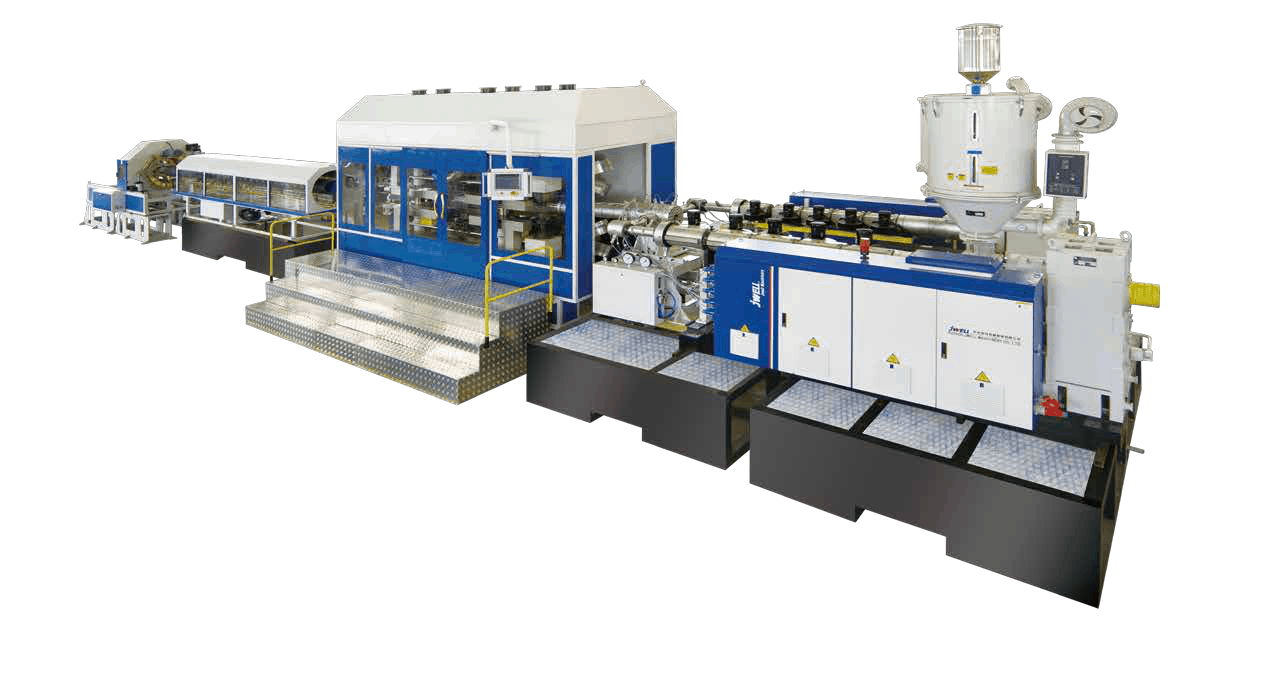

EVOH Anti-Oxygen Multi-layer Pipe Production Line

EVOH Anti-Oxygen multi-layer pipe has three layers and five layers structure, it has high weather resistance and blocking oxygen function. Stopping the microorganism go inside the pipe, preventing the corrosion of the metal part in the heating system. Mainly used for direct drinking water system and heating pipeline system, etc.

HDPE Multi-layer Co-extrusion Silicon Core Pipe Line

HDPE-Silicon duct Multi-layer co-extrusion pipe is a new composite pipe by the multi extruder co-extrusion, the main raw material is high-density polyethylene, the core layer is the lowest the friction coefficient of the solid lubricant silicone resin, better sealing performance, chemical corrosion resistance, widely used in optical cable communication network system.

EVA Multi-layer Co-extrusion Heat Shrinkage Pipe Line

EVA heat shrinkage multi-layer co-extrusion pipe, it is compound by the out layer with high quality soft cross-linked polyolefin materials and the inner layer with hot melt adhesive, has high-temperature shrinkage, fir resistant, insulation with anti-corrosion function. Widely used in electronic equipment wiring waterproof, anti-leakage, multi-strand wire harness sealing waterproof, wire and cable repair, and other industries.

FAQ

- International Commercial Terms(Incoterms): FOB, CFR, CIF, EXW

- Terms of Payment: LC, T/T

- Average Lead Time: Peak season lead time: 3-6 months, Off season lead time: 1-3 months

- Number of Foreign Trading Staff:>50 People

Yes, We own 5 manufacturing bases and sales center in Shanghai , Suzhou ,Changzhou, Zhou Shan, Dongguan China.

Jwell made the first Chinese screw and barrel in 1978 in brand name Jinhailuo.After more than 40 years development,

JWELL is one of the biggest extrusion machine supplier in China with 300design&test engineer, 3000 employees.

Jwell has become the premier supplier of extrusion lines and reliable business partners. Welcome to drop in us.

Our machines taking the European standards and follow the Germany type of business, we cooperation with

International famous brands Siemens Schneider Flender Omron ABB WEG Falk Fuji etc. Our company continuously

imports over 1000 international first-class high precision processing equipment such as multistage machining centers, CNC lathes and CNC milling machines from Korea, Japan etc. All our processes strictly adhere to CE certification,

IS09001 and 2008 quality management system . And we have 12 months quality warranty time. We testing the

machine performances before each delivery. Jwell service engineers will always be here for anything you needed.

Usually it takes about 1 – 4 months depends on different machinery upon receipt of order advance payment.

Once clear your requirements and determined extrusion line is ideal for you. We will send technical solutions and

Proforma Invoice to you. You can pay via TT bank transfer, LC as you like.

One. We provide both customized extrusion lines and technical solutions. Welcome contact with us for technical

innovation or improvements for your future purchasing plan.

We produce more than 2000 advanced extrusion lines every year world wide.

We can send the small spare parts by air express for urgent matter. And the complete production line by sea

to save the cost. You can either use your own assigned shipping agent or our cooperative forwarder. The nearest

port is China Shanghai, Ningbo port, which is convenient for maritime transportation..

Yes, we support our business partners by pre-after sale service. Jwell has more than 300 technical testing

engineers traveling world wide. Any cases would be responded with prompt solutions. We provide training, testing,

operation and maintenance service for a life time.

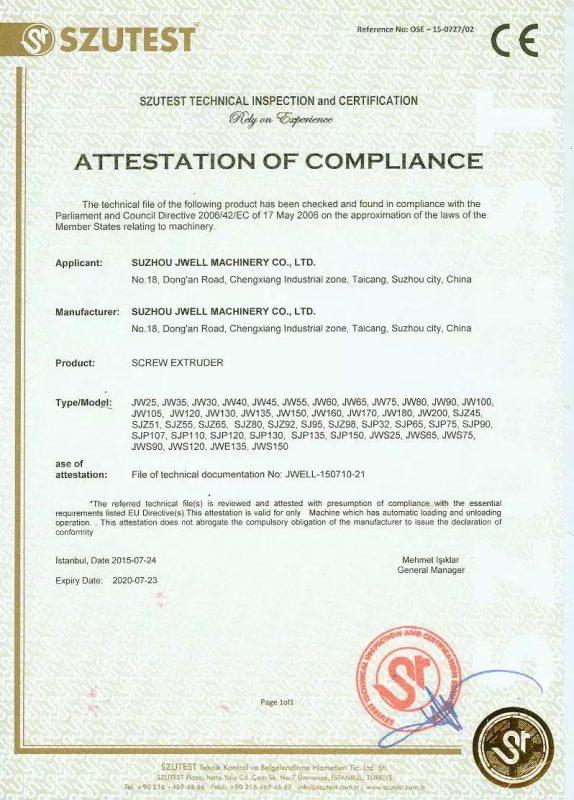

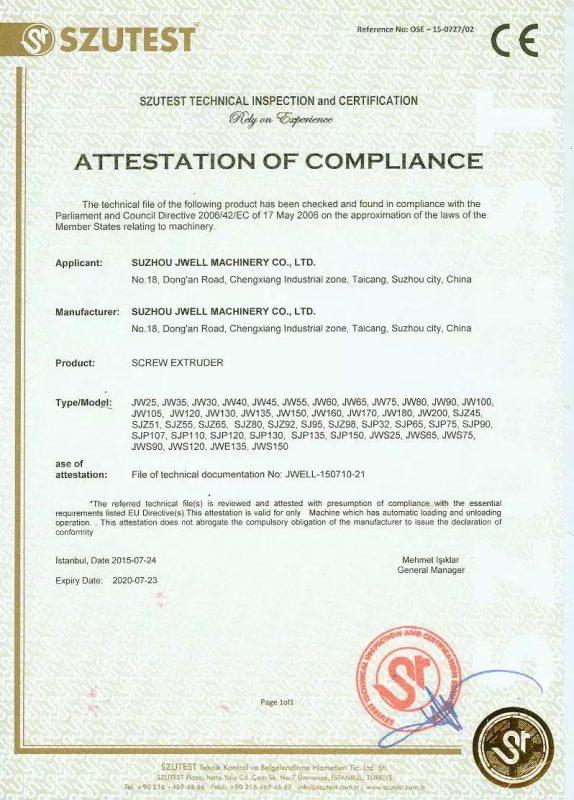

Certificates

Certified By:SGS

extrusion down stream equipment

Certified By:SGS

extrusion down stream equipment

Certified By:SGS

extrusion down stream equipment

Certified By:SGS

extrusion down stream equipment

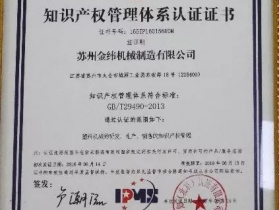

Certified By:Other

Design, Development, Manufacture and Sales of intellectual property rights management for Plastic Machine

Certified By:Other

Design, Development, Manufacture and Sales of Plastic Pipe and Sheet Extrusion Production Line

Certified By:Quality Austria Training, Certification and Evaluation Ltd

Plastic extrusion line