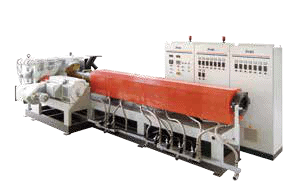

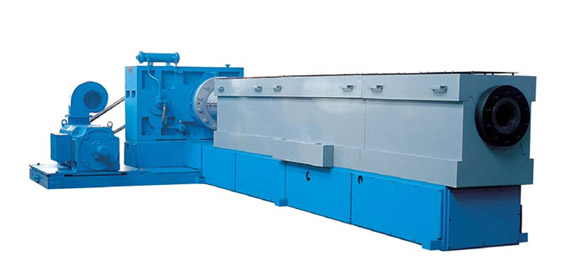

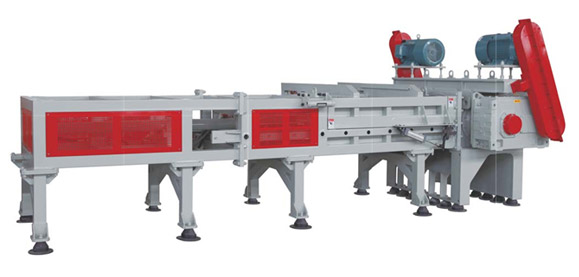

XPE/IXPE Foaming Coil Extrusion Line

Short Description:

product description our certificates FAQ request a quote Menu product description our certificates FAQ request a quote XPE/IXPE Foaming Coil Extrusion Line Performance & Advantages The structure of XPE foam material is an independent hole enclosure structure, it has the function of heat preservation and heat insulation. Meanwhile, it features noise-reducing, waterproof. And it has the properties of heat resistance, anti-aging, and environmental protection, ...

Product Detail

Product Tags

XPE/IXPE Foaming Coil Extrusion Line Performance & Advantages

The structure of XPE foam material is an independent hole enclosure structure, it has the function of heat preservation and heat insulation. Meanwhile, it features noise-reducing, waterproof. And it has the properties of heat resistance, anti-aging, and environmental protection, and its coil shape and lamination features, so this product can be widely used in central air conditioning projects, pipe projects, large containers, advanced composite layers; bag lining, packaging of the integrated circuit board, sole of advanced sports shoes, cushion and heat insulation for car, decoration material, floating material and single or double coat adhesive tape and so on.

The surface of IXPE is smooth, close and the vesicle is tiny and even. This product is widely used in building, chemical pipe, thermal projects, car and boat manufacture, package, agriculture, fishery, gym, and amusement fields.

XPE/IXPE Foaming Coil Extrusion Line Main technical specification

| Extruder | Screw

Diameter (mm) |

L/D | Screw

speed R/min |

Foaming

times |

Cooling

method |

Capacity

(Max.) Kg/h |

Products

width (mm) |

Products Thickness

(mm) |

Total

power (kW) |

| JWS90 | 90 | 25: 1 | 10-38 | 5-35 | Water

cooling |

80 | 1100 | 2.0-6.0 | 200 |

| JWS120 | 120 | 25: 1 | 10-38 | 5-35 | 120 | 1100-1300 | 2.0-6.0 | 315 | |

| JWS150 | 150 | 25: 1 | 10-38 | 5-35 | 180 | 1100-1400 | 3.0-12.0 | 400 | |

| JWS180 | 180 | 25: 1 | 10-38 | 5-35 | 220 | 1100-1600 | 3.0-12.0 | 450 |

XPE/IXPE Foaming Coil Extrusion Line production process:

Mixing and granulating machine (LDPE+AC, LDPE+DCP)-extruder squeezing sheet-foaming furnace foaming-back-end equipment-various products

XPE/IXPE Foaming Coil Extrusion Line (Jwell-150) single screw extrusion granulation unit technical configuration

- Operating materials and output: XPE foaming masterbatch, output 300-400kg/h

- Granulation process: 75L internal mixer—automatic elevator—double-wrist feeder—∮150 single screw extruder—hydraulic plate type automatic screen changer—air-cooled eccentric hot cutting pelletizing head—eccentric hot cutting Cover-secondary cyclone separator-vibrating screen-wind blowing silo

XPE foaming furnace performance advantages:

- The preheating and cross-linking sections have been greatly changed to reduce the heat capacity space while meeting the process requirements.

- Large output: Jwell three-stage furnace has the largest output (maximum 200 kg/hour or more), and XPE foam cells are denser than two-stage furnaces, and the gas consumption is equivalent to that of two-stage furnaces.

- Observation holes are set on the wall panels of the foaming section, and a baffle structure is set at the exit of the foaming furnace. The size of the furnace mouth is adjusted according to the conditions of the products produced, so as to achieve the effect of energy-saving.

- The maximum expansion ratio can reach 35-40 times.

Features of XPE chemical foam:

- Cushioning-semi-rigid foam, the original performance will not be lost even after strong impact;

- Formability-strong heat resistance, good ductility, uniform density;

- Sound absorption-it has the function of sound absorption and noise reduction, which is suitable for sound-absorbing and sound-proof materials in strong noise equipment such as airplanes and automobiles and the environment;

- Thermal insulation-its fine independent bubble structure can effectively reduce the energy exchange caused by air convection. XPE also has the properties of non-toxic, odorless, chemical resistance, oil resistance, acid resistance, halogen resistance, and other various chemicals.

Due to the above characteristics of XPE, XPE has a wide range of applications and needs in different industries. In the early stage, it was mainly used in the field of home appliances and the automotive industry. Later, it was gradually promoted to the construction, sporting goods, medical industry, and relatively high-standard packaging industries.

Main application areas of XPE products

1.Car mats and thermal insulation materials

The early product material is Kelin blanket + EVA, now it is generally leather + XPE + quilted embroidery. XPE is a polyethylene foam material that is soft and wear-resistant. It is heat-covered with leather and is a synthetic type. With a quilting embroidery machine, a variety of fully enclosed foot pads can be produced. The whole process does not require glue, which is safe and environmentally friendly.

2.Climbing mat

At present, the commonly used materials of crawling mats are mainly divided into four types: EVA, EPE, PVC, and XPE. Most of the common color block splicing mats on the market are made of EVA, and XPE is more cost-effective and safe, and non-toxic.

3.XPE 3D stereo wall sticker

3D three-dimensional self-adhesive wall stickers, environmentally friendly and tasteless, light material, anti-collision and sound insulation, zero construction cost, it is the first choice for decoration materials for secondary simple decoration.

Three-dimensional wall stickers mainly have the following characteristics:

- The texture is soft and elastic, which can better prevent the impact on children. The 3D three-dimensional brick pattern, excellent material, and elegant outline create a simple and pure style. Thicken the brick pattern, play a better sound insulation effect.

- The decoration is convenient and easy to clean, easy to paste, the back comes with adhesive, just tear off the bottom paper, and then paste it on the smooth surface, the surface is waterproof and antifouling material, and it can be directly scrubbed with a wet cloth, which is convenient and quick. Even if you want to redecorate in the future, just tear off the original product and you can start a new decoration with a wet cloth, which is convenient and quick.

- Long shelf life, as long as the surface is not damaged by strong impact, the material itself will not deteriorate.

- Construction and decoration industry

- Floating floor slab cushion

The shock-absorbing pad made of polyethylene XPE or IXPE foam material has the advantages of good sound insulation, waterproof and moisture-proof, environmental protection, and odorless, and is a professional soundproof material to solve the problem of floor vibration.

Due to the excellent performance of XPE itself, it solves the shortcomings of moisture absorption, rot, insects, and the high cost of traditional floating floor slabs such as corkboard, sugarcane board, glass wool, etc., providing a sound insulation system for modern building floating floor slabs The best solution is a low-cost thermal insulation material suitable for large-scale applications, suitable for general multi-story residential buildings, commercial buildings, computer rooms and other sound channeling places.

4.Silent and shock-absorbing materials laid under the floor

Used as (SPC, WPC, LVT) composite flooring, solid wood flooring, and other moisture-proof, silent mats, packaging materials, etc.

Main functions: moisture-proof and silent. Because the surface of the product is covered with a PE moisture-proof film, it has lightweight, has good elasticity, has corrosion resistance, has long-term use without deformation, and can be recycled, which more reflects the environmental protection characteristics of XPE.

5.Materials used in roofs or other special thermal insulation environments

XPE heat insulation material utilizes the excellent barrier performance of the heat insulation material with the dual effect of aluminum film heat reflection and light reflection, coupled with the heat insulation performance of XPE and high-density fire protection function, the two-two combination of XPE and aluminum foil makes XPE heat insulation material in It has more advantages in the same type of insulation materials.

FAQ

- International Commercial Terms(Incoterms): FOB, CFR, CIF, EXW

- Terms of Payment: LC, T/T

- Average Lead Time: Peak season lead time: 3-6 months, Off season lead time: 1-3 months

- Number of Foreign Trading Staff:>50 People

Yes, We own 5 manufacturing bases and sales center in Shanghai , Suzhou ,Changzhou, Zhou Shan, Dongguan China.

Jwell made the first Chinese screw and barrel in 1978 in brand name Jinhailuo.After more than 40 years development,

JWELL is one of the biggest extrusion machine supplier in China with 300design&test engineer, 3000 employees.

Jwell has become the premier supplier of extrusion lines and reliable business partners. Welcome to drop in us.

Our machines taking the European standards and follow the Germany type of business, we cooperation with

International famous brands Siemens Schneider Flender Omron ABB WEG Falk Fuji etc. Our company continuously

imports over 1000 international first-class high precision processing equipment such as multistage machining centers, CNC lathes and CNC milling machines from Korea, Japan etc. All our processes strictly adhere to CE certification,

IS09001 and 2008 quality management system . And we have 12 months quality warranty time. We testing the

machine performances before each delivery. Jwell service engineers will always be here for anything you needed.

Usually it takes about 1 – 4 months depends on different machinery upon receipt of order advance payment.

Once clear your requirements and determined extrusion line is ideal for you. We will send technical solutions and

Proforma Invoice to you. You can pay via TT bank transfer, LC as you like.

One. We provide both customized extrusion lines and technical solutions. Welcome contact with us for technical

innovation or improvements for your future purchasing plan.

We produce more than 2000 advanced extrusion lines every year world wide.

We can send the small spare parts by air express for urgent matter. And the complete production line by sea

to save the cost. You can either use your own assigned shipping agent or our cooperative forwarder. The nearest

port is China Shanghai, Ningbo port, which is convenient for maritime transportation..

Yes, we support our business partners by pre-after sale service. Jwell has more than 300 technical testing

engineers traveling world wide. Any cases would be responded with prompt solutions. We provide training, testing,

operation and maintenance service for a life time.

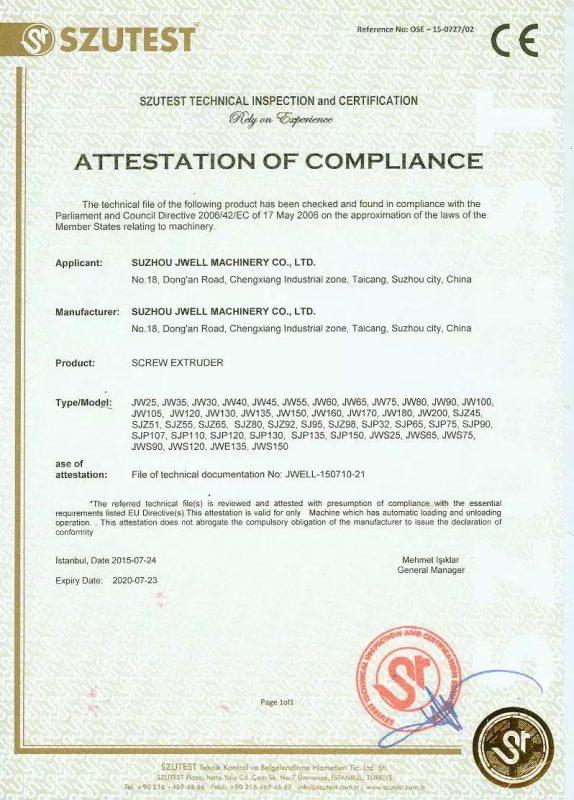

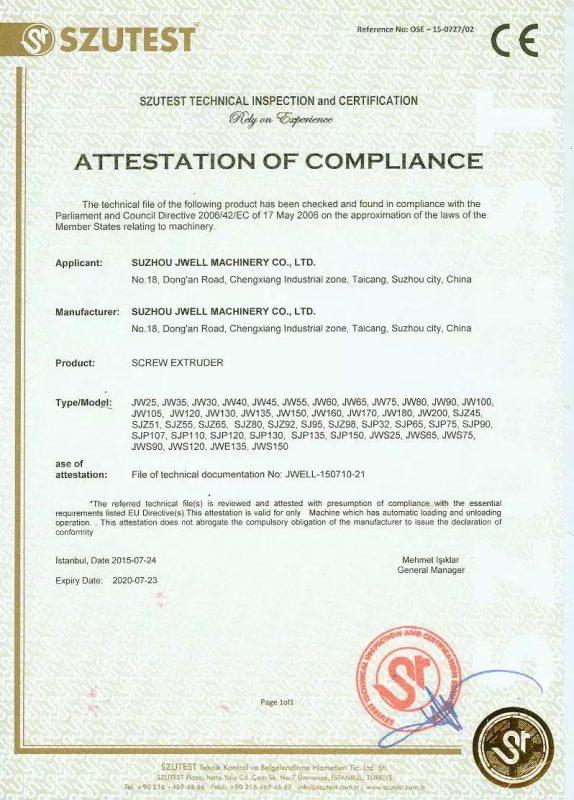

Certificates

Certified By:SGS

extrusion down stream equipment

Certified By:SGS

extrusion down stream equipment

Certified By:SGS

extrusion down stream equipment

Certified By:SGS

extrusion down stream equipment

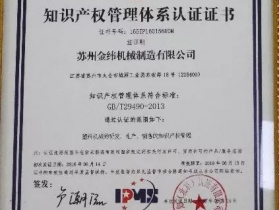

Certified By:Other

Design, Development, Manufacture and Sales of intellectual property rights management for Plastic Machine

Certified By:Other

Design, Development, Manufacture and Sales of Plastic Pipe and Sheet Extrusion Production Line

Certified By:Quality Austria Training, Certification and Evaluation Ltd

Plastic extrusion line